Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques

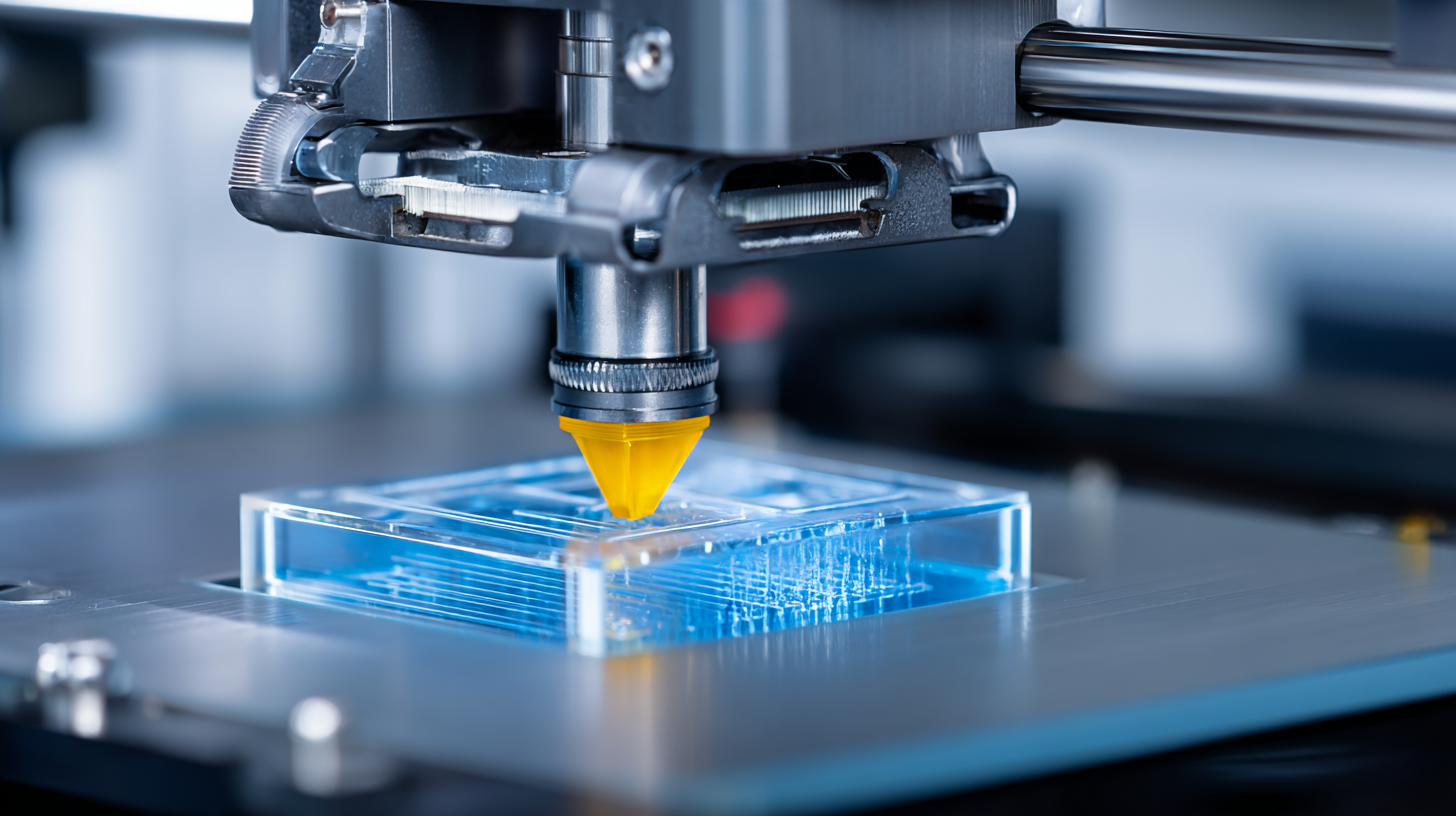

In the fast-evolving landscape of manufacturing, rapid injection molding has emerged as a game-changer, offering speed and precision that meet the increasing demands of various industries. As we look towards 2025, understanding the latest specifications and techniques in rapid injection molding becomes crucial for companies aiming to stay competitive.

This comprehensive guide delves into the essential aspects of rapid injection molding, illuminating the best practices and innovations shaping the future of the industry. From material selection to mold design, we will explore how these advancements are driving efficiency and reducing time-to-market.

With the right insights and strategies, businesses can harness the full potential of rapid injection molding, ensuring they are well-equipped for the challenges and opportunities that lie ahead in this dynamic field.

The Evolution of Rapid Injection Molding in China: A Quality-Driven Approach

The landscape of rapid injection molding in China has witnessed remarkable evolution, driven by an increasing focus on quality and efficiency. According to a report by Research and Markets, the Chinese rapid injection molding market is projected to reach USD 2.7 billion by 2025, reflecting a compound annual growth rate (CAGR) of 9.2%. This growth is largely attributed to the demand for precision components in industries such as automotive, consumer electronics, and medical devices.

Moreover, Chinese manufacturers are adopting advanced technologies such as digital twin simulations and automation in production lines. A study conducted by McKinsey & Company indicates that the implementation of Industry 4.0 practices can reduce production time by up to 25% while enhancing overall quality control. As companies prioritize sustainability alongside efficiency, practices such as using biodegradable materials and optimizing energy usage are becoming commonplace, further solidifying China's commitment to producing high-quality rapid injection molded products that meet international standards.

Rapid Injection Molding Efficiency Trends in China (2021-2023)

This bar chart illustrates the increasing efficiency of rapid injection molding processes in China from 2021 to 2023. The data shows a steady improvement in efficiency, emphasizing the quality-driven approach in the industry.

Key Specifications for Achieving Precision in Rapid Injection Molding

In the realm of rapid injection molding, achieving precision is paramount for producing high-quality parts. Key specifications such as cycle time, mold temperature, and material selection significantly influence the outcome. Industry reports indicate that cycle time can be reduced to as low as 15 seconds in advanced systems, optimizing production efficiency while maintaining dimensional accuracy. A tightly controlled mold temperature, typically maintained between 60°C to 80°C, is critical for minimizing warping and ensuring consistent material flow, which is essential for high-precision applications.

Material selection also plays a crucial role in achieving precision. According to the latest data from the 2023 Global Plastics Production Trends, materials such as thermoplastics and engineered resins are gaining traction due to their superior mechanical properties and stability. Selecting the right resin not only affects the durability of the final product but also impacts the precision of mold filling and cooling. A well-designed injection molding process that incorporates these specifications can lead to production tolerances as tight as ±0.01 mm, meeting the stringent demands of industries like aerospace and medical devices, where precision is non-negotiable.

Innovative Techniques to Enhance Efficiency and Reduce Costs in Manufacturing

In the fast-paced world of manufacturing, efficiency and cost reduction are paramount. Rapid injection molding has emerged as a game changer, not only streamlining production processes but also enabling companies to deliver high-quality products faster. One innovative technique to enhance efficiency is the implementation of

advanced mold design software. This technology allows engineers to simulate the injection molding process, identifying potential issues before production begins. By optimizing mold flow and cooling patterns, manufacturers can significantly reduce cycle times, leading to quicker turnarounds and lower operational costs.

Quality Control Practices That Elevate Global Standards in Chinese Manufacturing

In the realm of global manufacturing, quality control practices play a pivotal role in determining the competitiveness and reputation of Chinese products. For companies engaged in rapid injection molding, implementing rigorous quality control protocols is essential not only to meet domestic demands but also to adhere to international standards. This involves regular inspections, thorough testing of materials, and the use of advanced technology to monitor every stage of production. By integrating such practices, manufacturers can significantly reduce defects and enhance product reliability, positioning themselves favorably in the global market.

Moreover, elevating quality control standards is not merely about compliance; it’s a strategic move that fosters innovation and efficiency. Companies that prioritize quality are often more agile in responding to market changes, allowing them to introduce new, high-demand products faster. Techniques such as Six Sigma and Total Quality Management (TQM) provide frameworks for streamlined processes and continuous improvement. As Chinese manufacturers strive to elevate their global standing, adopting these practices will not only enhance their product quality but also build stronger relationships with international partners, ensuring sustained growth and success in an increasingly competitive environment.

The Future of Rapid Injection Molding: Trends and Technologies Shaping the Industry

The landscape of rapid injection molding is undergoing a significant transformation, driven by innovative technologies and emerging trends that are reshaping the industry. One of the most notable advancements is the integration of advanced materials, which allows for better performance and durability of molded parts. As companies increasingly demand customized solutions at a faster pace, the utilization of high-performance thermoplastics and bio-based materials is becoming more prevalent. These developments not only enhance the physical properties of molds but also contribute to sustainability efforts within manufacturing.

Additionally, automation and smart manufacturing technologies are playing a crucial role in the evolution of rapid injection molding. With the advent of Industry 4.0, data analytics and IoT (Internet of Things) have enabled real-time monitoring and control of the molding process. This not only improves efficiency but also significantly reduces waste. Furthermore, the use of artificial intelligence in predictive maintenance is set to streamline operations, minimize downtime, and ultimately lower production costs. As these trends continue to evolve, they promise to unlock new levels of precision and efficiency in the injection molding industry, paving the way for a more sustainable and innovative future.