5 Essential Tips for Sourcing Small Run Plastic Injection Molding: A Global Buyer’s Guide

In the ever-evolving landscape of manufacturing, small run plastic injection molding has emerged as a vital solution for businesses aiming to streamline their production processes while maintaining quality and cost-effectiveness. Whether you are a startup looking to bring a new product to market or an established company needing to produce limited quantities of specialized components, understanding the nuances of sourcing can significantly enhance your operational efficiency. This global buyer's guide will explore five essential tips for successfully navigating the complexities of small run plastic injection molding, from selecting the right suppliers to optimizing lead times. By equipping yourself with these insights, you can make informed decisions that not only meet your production needs but also position your business for future growth in a competitive market.

Understanding the Basics of Plastic Injection Molding for Small Runs

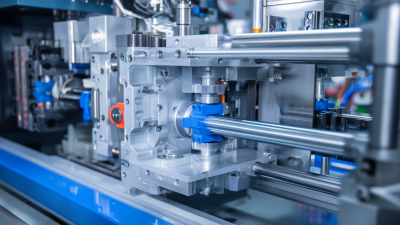

Understanding the fundamentals of plastic injection molding is crucial for those looking to source small run production effectively. The process involves three primary components: the clamping device, the plasticizing device, and the drive unit. The clamping system holds the mold in place during the injection process, ensuring precise formation of the plastic part. Proper calibration of these components is key to achieving consistent results, especially when producing smaller batch sizes, which often require careful attention to detail to reduce scrap material and enhance efficiency.

One advanced technique worth noting is Microcellular Injection Molding (MIM), particularly when combined with rapid heat cycle molding (RHCM). This innovative approach facilitates the creation of microcellular foamed plastic parts, which can offer significant advantages in terms of weight reduction and strength. By optimizing the mold temperature during the injection process, manufacturers can effectively control the formation of a porous structure in the final product. Understanding these techniques is essential for global buyers looking to improve their sourcing strategies and meet specific project requirements.

Identifying and Evaluating Reliable Global Suppliers for Small Production

When sourcing small run plastic injection molding, identifying and evaluating reliable global suppliers is paramount. Start by researching potential suppliers through industry directories, forums, and networking with peers. Look for companies that specialize in small production runs, as they tend to have the expertise and flexibility required to accommodate unique project needs. Pay attention to their production capabilities, minimum order quantities, and lead times to ensure they align with your specific requirements.

Once a list of potential suppliers is generated, it’s crucial to assess their reliability and quality standards. Request samples of their previous work to evaluate the quality of their products and finish. Additionally, consider their certifications and adherence to international quality standards, which can be indicative of their commitment to excellence. Engage in discussions about their manufacturing processes and technologies to gauge their ability to innovate and solve potential problems that may arise during production. By thoroughly vetting suppliers, you can secure reliable partners who will help bring your vision to life in the realm of plastic injection molding.

Cost Factors to Consider When Sourcing Small Run Injection Molding

When sourcing small run plastic injection molding, understanding the cost factors is crucial to making informed decisions. According to the latest industry report by Grand View Research, the global injection molding market is projected to reach $453.3 billion by 2027, with small-run projects gaining popularity due to their flexibility and rapid prototyping capabilities. Factors such as material choice, processing time, and tooling costs significantly influence the overall pricing structure. For reference, the average cost of tooling can range from $3,000 to $100,000, depending on complexity, which underscores the importance of meticulous planning to keep expenses manageable.

Another significant consideration is the choice of suppliers. Reports from the Plastics Industry Association indicate that sourcing from regions with established manufacturing hubs, such as Asia or Eastern Europe, can help lower costs due to economies of scale. However, this must be balanced with shipping and potential tariffs, which could inflate costs unexpectedly. Additionally, factors like the volume of parts ordered—typically fewer than 5,000 units for small runs—can affect per-unit pricing, often pushing it higher than larger-scale productions. Buyers must evaluate these considerations carefully to optimize their sourcing strategy for small run injection molding.

5 Essential Tips for Sourcing Small Run Plastic Injection Molding

| Tip Number | Tip Description | Cost Factors | Time Considerations |

|---|---|---|---|

| 1 | Choose the Right Material | Material costs vary; consider bulk options. | Material lead time can affect production schedule. |

| 2 | Evaluate Tooling Options | Initial tooling costs can be high; consider options. | Tooling development needs time—factor this into your timeline. |

| 3 | Understand Production Runs | Smaller runs typically have higher costs per unit. | Consider production speed for small run efficiency. |

| 4 | Select Experienced Suppliers | Quality comes with experience; verify supplier credentials. | Supplier lead times can impact total delivery schedule. |

| 5 | Negotiate Pricing Terms | Understand all cost components; negotiate effectively. | Ensure invoicing aligns with production cycles. |

Key Questions to Ask Suppliers Before Committing to a Project

When sourcing small run plastic injection molding, asking the right questions is crucial for ensuring a successful partnership with suppliers. Start by inquiring about their production capabilities. According to a report by MarketsandMarkets, the global plastic injection molding market is expected to reach USD 366.6 billion by 2026, indicating a growing capacity among suppliers. Understanding their machine capabilities, turnaround times, and the types of materials they can work with will help you assess whether they can meet your project requirements.

Another vital area to explore is the supplier’s quality assurance processes. According to a study published in the Journal of Polymer Engineering, defects in injection molded parts can exceed 30% without rigorous quality checks, leading to increased costs and delays. Ensure that the supplier utilizes advanced technologies, such as real-time monitoring and Statistical Process Control (SPC), to maintain high quality throughout the production cycle. Additionally, inquire about their experience with similar projects and their approach to resolving potential issues, as these factors will significantly impact the success of your engagement.

Supplier Assessment for Plastic Injection Molding

This chart illustrates the evaluation criteria for sourcing suppliers for small run plastic injection molding. The key parameters include Price, Lead Time, Quality Assurance, Communication, and Technical Expertise, with scores reflecting the relative importance of each criterion in the selection process.

Ensuring Quality Control and Compliance in Small Run Production

In today's competitive landscape, ensuring quality control and compliance in small run plastic injection molding is paramount for global buyers. As companies increasingly digitize their processes, integrating advanced technologies can lead to significant improvements in production efficiency and product integrity. Recent insights highlight that industrial software is transforming traditional manufacturing methods. By leveraging AI-driven platforms, businesses can optimize production workflows, thereby ensuring adherence to quality standards throughout the molding process.

Moreover, the evolving regulatory environment, particularly the tightening of safety regulations in the EU, underscores the necessity for robust compliance frameworks. Products manufactured for the European market must meet stringent criteria as set forth by the RED directive. This not only emphasizes the importance of quality in small run production but also the criticality of collaborating with suppliers who are well-versed in these regulatory requirements.

According to market projections, the global market for marking solutions is anticipated to grow from $766.83 million in 2025 to $2.42947 billion by 2034, reflecting the increasing demand for compliance and quality assurance in manufacturing. This growth underlines the importance of choosing the right partners and technologies to enhance product quality and compliance in small run plastic injection molding.

Related Posts

-

Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape

-

10 Reasons Rapid Injection Molding is the Best Choice for Your Production Needs

-

Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

Global Success of Medical Injection Molding from China Driven by Quality Enhancement