9 Essential Tips for Successful Small Run Injection Molding Processes

In the fast-paced world of manufacturing, "small run injection molding" emerges as a game-changer, enabling companies to produce limited quantities of high-quality products efficiently. Industry expert Dr. Susan Miller, a recognized authority in polymer processing, asserts, "The ability to pivot quickly and produce small batches can significantly enhance a company's responsiveness to market demands." This adaptability not only reduces inventory costs but also allows for rapid prototyping and testing, ultimately leading to better product designs.

Understanding the nuances of small run injection molding is crucial for achieving successful outcomes. Each small batch presents unique challenges, from material selection to mold design, and requires a refined approach to ensure precision and quality. As companies increasingly seek to personalize products and reduce waste, mastering this manufacturing technique becomes essential. In this article, we will explore nine essential tips that will guide manufacturers through the complexities of small run injection molding, equipping them to thrive in a competitive landscape while satisfying their customer's evolving needs.

Understanding the Basics of Small Run Injection Molding Techniques

Small run injection molding is an increasingly popular method for manufacturers looking to produce limited quantities of parts with high precision. According to a report by Grand View Research, the global injection molding market was valued at approximately $294 billion in 2020, with a significant segment dedicated to small batch production. This technique allows companies to create custom components without the hefty upfront costs associated with large-scale manufacturing, making it ideal for startups and niche markets.

Understanding the basics of small run injection molding involves acknowledging the technical aspects that can affect production efficiency and quality. Key factors include material selection, mold design, and cycle times. For instance, selecting the right thermoplastic material is crucial; industry studies show that using advanced materials can enhance durability and reduce scrap rates by up to 20%. Proper mold design also plays a vital role, as a well-designed mold can diminish cycle times significantly, thereby increasing overall productivity. Firms that optimize these elements not only improve their bottom line but also enhance customer satisfaction by delivering high-quality parts consistently.

Choosing the Right Materials for Your Injection Molding Projects

Choosing the right materials for your injection molding projects is critical for ensuring both the quality and functionality of the finished product. According to the Plastics Industry Association, the demand for engineered thermoplastics is projected to increase by 4.6% annually through 2025, driven by advancements in material technology and their application in various industries, including automotive and consumer goods. These high-performance materials, like polycarbonate and nylon, offer superior mechanical properties and thermal resistance, making them ideal for small run injection molding where precision and durability are paramount.

Moreover, evaluating the processing characteristics of materials is essential. For instance, small run injection molding often requires faster cycle times and cost-effective material usage. Reports from the Society of the Plastics Industry present that optimizing the material type can reduce cycle times by up to 30%, significantly impacting production efficiency. Selecting materials that not only meet the design specifications but also facilitate smooth processing under these conditions can lead to better yields and less waste, aligning with the industry's push towards sustainability in manufacturing practices.

Optimizing Mold Design for Efficient Production and Quality

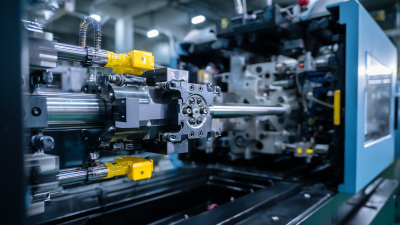

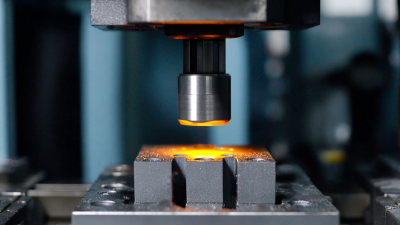

Optimizing mold design is crucial for achieving efficiency and quality in small run injection molding processes. The initial step in this optimization is selecting the right materials for both the mold and the product. High-grade steel or aluminum should be considered for molds, as they enhance durability and can withstand the pressures of repeated use. Additionally, the use of precise finishing techniques can significantly reduce surface defects and improve the overall aesthetics of the final product.

Another critical aspect is the layout and cooling channels of the mold. A well-designed cooling system significantly reduces cycle times and maintains consistent temperature throughout the molding process. Strategic placement of cooling channels allows for uniform cooling and minimizes warping and shrinkage in the molded parts. Engineers should also consider implementing flow simulation software during the design phase to predict flow patterns and identify potential problem areas before production begins. This proactive approach not only enhances the quality of the molded parts but also streamlines the production process, leading to optimal outcomes in small run injection molding.

9 Essential Tips for Successful Small Run Injection Molding Processes

| Tip Number | Tip Description | Impact on Production | Quality Rating (1-5) |

|---|---|---|---|

| 1 | Design for manufacturability | Reduces production time and cost. | 5 |

| 2 | Optimize gate location | Improves material flow and reduces defects. | 4 |

| 3 | Use simulation tools | Identifies issues before production starts. | 5 |

| 4 | Select appropriate materials | Enhances product durability and performance. | 4 |

| 5 | Implement proper cooling techniques | Increases cycle time and reduces warpage. | 5 |

| 6 | Conduct regular maintenance on molds | Reduces downtime and defects. | 5 |

| 7 | Train operators thoroughly | Minimizes human error during production. | 4 |

| 8 | Monitor production metrics | Enables continuous improvement. | 5 |

| 9 | Establish clear communication | Enhances collaboration among team members. | 4 |

Controlling Temperature and Pressure for Consistent Output

Achieving consistent output in small run injection molding processes largely hinges on the meticulous control of temperature and pressure. Maintaining the right temperature throughout the molding cycle is crucial, as it directly affects the viscosity of the material being injected. A uniform temperature ensures that the plastic flows smoothly into the mold, reducing defects and improving surface finish. Regularly calibrate your heating elements and thermocouples to prevent fluctuations that can disrupt the production process.

Pressure control is equally important in ensuring a successful small run injection molding operation. High pressure is essential for forcing the molten material into intricate mold details; however, excessive pressure can cause flash or deformation. It's beneficial to employ pressure monitoring systems to maintain the ideal levels, adjusting parameters in real-time during production. Additionally, consider implementing a pressure hold phase at the end of the injection phase to allow for any material shrinkage, ensuring the mold is filled completely and consistently.

By focusing on these temperature and pressure controls, you’ll promote a stable molding environment that not only enhances the quality of your outputs but also increases the efficiency of your small run production processes.

Implementing Quality Assurance Measures Throughout the Process

Implementing quality assurance measures throughout the injection molding process is critical for achieving consistent results, especially in small run production settings. To start, it is essential to establish a robust quality management system that integrates inspection points at various stages of the molding cycle. This includes evaluating materials before they enter the molding machine, ensuring that they meet the required specifications, and conducting in-process inspections to monitor key parameters such as temperature, pressure, and cycle times. By doing so, manufacturers can identify and mitigate defects early in the process.

Furthermore, maintaining a feedback loop for continuous improvement is vital. This involves collecting data on production outcomes and using it to refine both the molding process and the quality assurance measures. Training employees to recognize potential quality issues and empowering them to take corrective actions can significantly enhance overall product quality. Regular audits of the quality assurance protocols also help ensure that they remain effective and aligned with industry best practices, thereby optimizing efficiency and reducing waste in small run injection molding processes.

Related Posts

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

Mastering the Art of Injection Molded Parts Production A Comprehensive Tutorial on Techniques and Best Practices

-

Ultimate Guide to Small Run Plastic Injection Molding for Global Buyers

-

How to Maximize Efficiency in Small Volume Injection Molding: Industry Insights and Best Practices

-

Unlocking the Potential of Small Run Injection Molding for Rapid Prototyping and Cost Efficiency

-

10 Reasons Rapid Injection Molding is the Best Choice for Your Production Needs