What is an Injection Machine and How Does it Transform Manufacturing

The injection machine is a pivotal technology in modern manufacturing, playing a crucial role in the production of a diverse range of products, from automotive parts to consumer goods. According to a report by MarketsandMarkets, the global injection molding machine market is projected to reach USD 9.1 billion by 2026, growing at a CAGR of 3.8% from 2021 to 2026. This growth underscores the increasing reliance of manufacturers on injection machines to enhance efficiency and reduce production costs. By utilizing advanced techniques in injection molding, these machines not only streamline the manufacturing process but also enable high precision and superior quality of the final products. As industries continue to embrace automation and innovation, the injection machine stands out as a transformative force, redefining how manufacturers approach production challenges in an ever-evolving market landscape.

Understanding Injection Molding: The Basics and Its Role in Manufacturing Innovation

Injection molding is a pivotal technology that drives manufacturing innovation across various industries. At its core, this process involves injecting molten material into a mold to create precise and complex parts, enabling high-volume production with minimal waste. According to a recent analysis, the injection molding market continues to expand, with a projected growth rate of over 5% annually through 2027, showcasing its critical role in the advancement of manufacturing methods.

Innovations in this domain, such as advancements in thermoplastics and the emergence of eco-conscious materials, are reshaping the landscape. For instance, companies are increasingly adopting sustainable practices to reduce their environmental footprint, reflecting a broader industry trend towards greener manufacturing. Moreover, developments in specialized applications, like ceramic additive manufacturing, highlight the versatility and potential of injection molding techniques in creating advanced components for various sectors, including automotive and electronics. The ongoing integration of high-tech materials is set to further enhance the efficiency and capabilities of this essential manufacturing process.

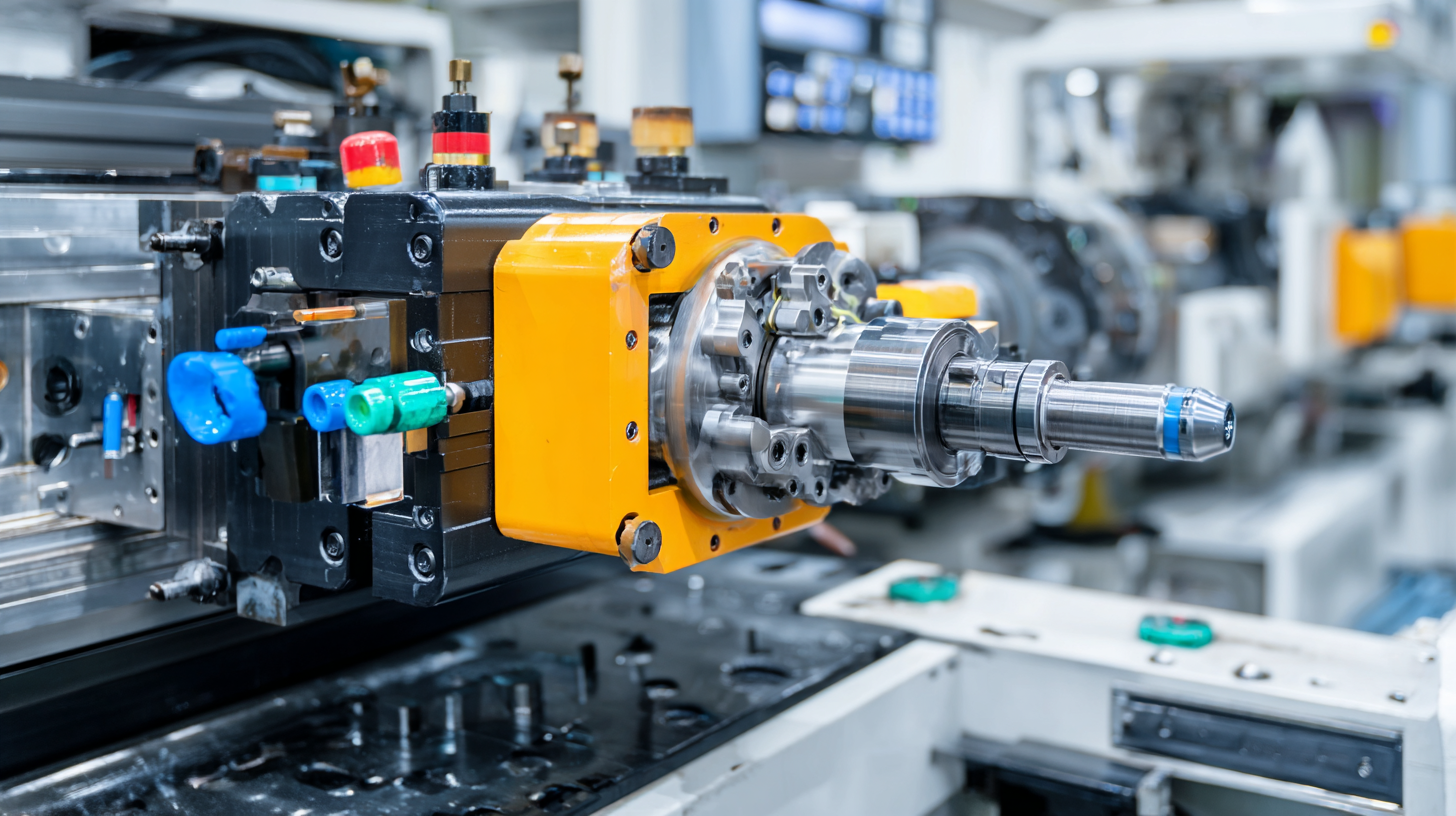

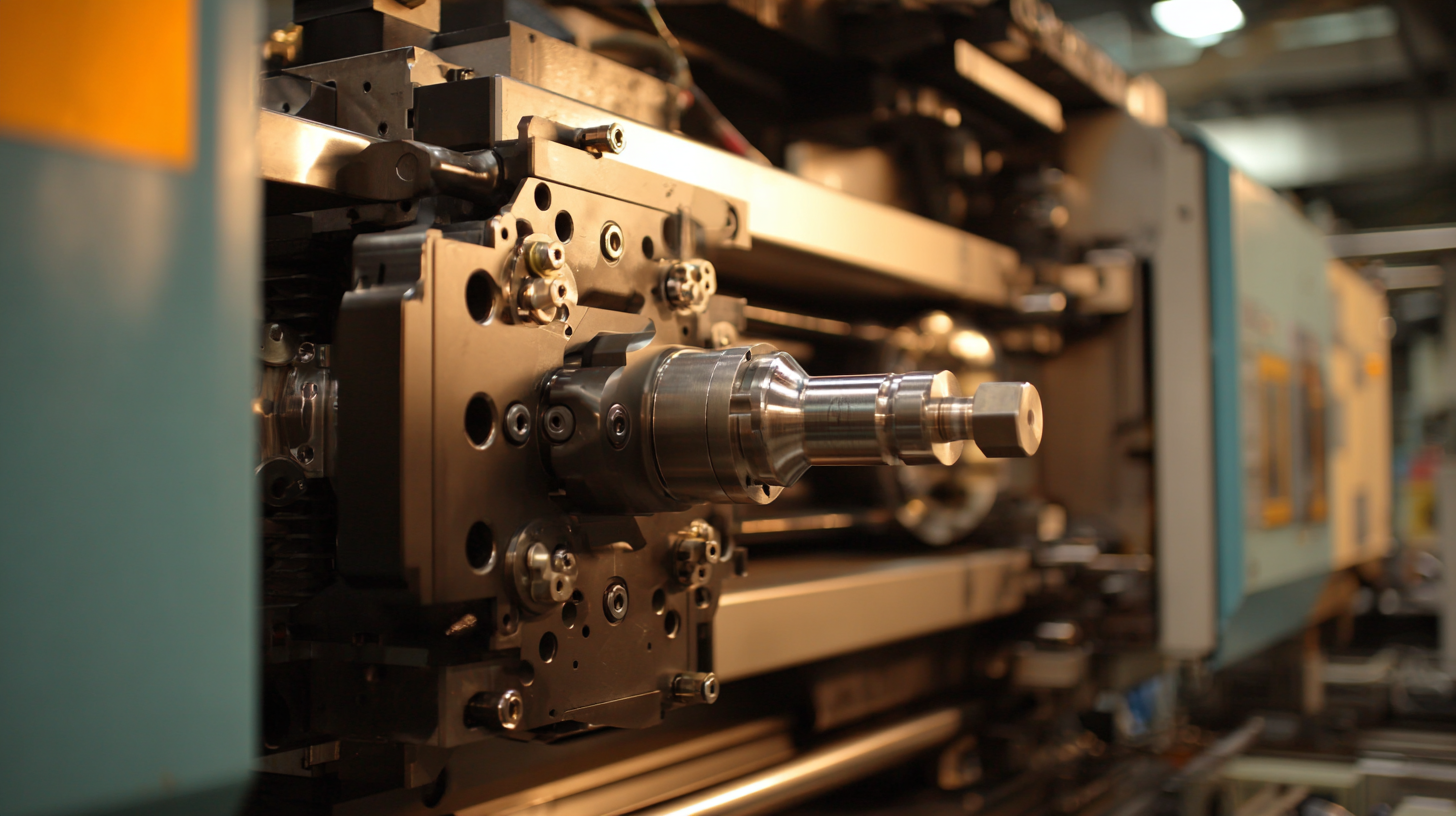

Key Components of Injection Machines: Mechanics Behind the Process of Plastic Production

Injection machines are complex pieces of equipment used in the plastic production process, consisting of several key components that work together to transform raw materials into finished products. At the heart of the injection machine is the injection unit, which consists of a hopper, screw, and barrel. The hopper feeds plastic pellets into the barrel, where the screw rotates to melt the plastic and inject it into the mold. This melting process is crucial, as it prepares the material for molding by ensuring it is uniformly heated and free of impurities.

Another essential component is the clamping unit, which holds the mold in place during the injection process. Clamps apply considerable force to keep the mold closed and prevent any leakage of molten plastic. This unit must be robust to withstand the pressures exerted during injection. Additionally, the cooling system plays a significant role in solidifying the injected plastic once it fills the mold, ensuring the final product retains its shape and quality. These mechanics behind injection machines not only enhance precision in manufacturing but also enable the efficient production of a wide range of plastic components across various industries.

Injection Machine Production Insights

The Efficiency of Injection Molding: How It Reduces Waste and Maximizes Output in Manufacturing

Injection molding has revolutionized the manufacturing sector by introducing remarkable efficiency that reduces waste and maximizes output. According to a report from Grand View Research, the global injection molding market was valued at approximately $236.6 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2022 to 2030. This growth highlights the industry's shift towards more efficient production methods that not only enhance productivity but also minimize environmental impact.

One of the primary benefits of injection molding is its high material utilization rate. The process is designed to produce precise and complex components with minimal excess material. Industry studies indicate that injection molding can achieve material waste rates as low as 2%, compared to traditional manufacturing methods that may generate as much as 20% waste. By reducing scrap and optimizing cycle times, manufacturers can significantly lower production costs while increasing the quality of the finished product. As businesses continue to adopt sustainable practices, the efficiency of injection molding positions it as a critical technology in modern manufacturing strategies.

Market Trends: Growth of Injection Molding Technology and Its Economic Impact on the Industry

The injection molding market is undergoing significant transformation, fueled by advancements in technology and rising demand for efficient manufacturing solutions. The global plastic injection molding market, valued at approximately $191 billion in 2023, is projected to reach $235.7 billion by 2025, highlighting a robust growth trajectory. This surge is attributed to the increasing adoption of injection molding across various industries, including automotive, consumer goods, and electronics, where precision and scalability are paramount.

In addition, the injection molding machine market itself is witnessing impressive growth, expected to exceed $10.4 billion in 2024 and to grow at a compound annual growth rate (CAGR) of 4.8% from 2025 to 2034. This expansion reflects the industry's shift towards more specialized machinery that enhances production efficiency and allows for intricate designs, leading to reductions in both waste and costs. Moreover, the molded plastic market is anticipated to expand from $758.69 billion in 2025 to approximately $1,218.39 billion by 2033, showcasing the increasing reliance on injection molding processes to meet diverse consumer needs across the globe.

Future Outlook: Innovations in Injection Machine Technology and Their Potential to Transform Manufacturing

The injection machine market is undergoing rapid evolution, with significant innovations promising to reshape manufacturing processes. The projected market value of LIM and LSR injection machines is set to reach $159.5 million in 2024, ultimately growing to $283.83 million by 2032, reflecting a robust growth rate of 7.47%. This rise is largely driven by advancements in technology that improve efficiency, reduce waste, and enhance product quality.

One notable trend is the integration of smart technology in injection molding machines. This includes automation and data analytics, allowing manufacturers to optimize production in real-time and predict maintenance needs. These innovations not only streamline operations but also empower businesses to achieve higher levels of customization and flexibility in production.

Tips: When considering the adoption of advanced injection machines, businesses should evaluate their specific production needs and look for features that offer scalability. Additionally, investing in training for staff on new technologies can significantly enhance productivity and reduce downtime. Lastly, keeping an eye on emerging trends can help companies stay competitive in a rapidly evolving market.

Related Posts

-

Ultimate Guide to Choosing the Right Injection Machine for Your Manufacturing Needs

-

The Definitive Ultimate Guide to Sourcing the Perfect Injection Machine for Your Business Needs

-

How to Maximize Efficiency in Small Volume Injection Molding: Industry Insights and Best Practices

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

How to Optimize Your Supply Chain for Plastic Manufacturing Success

-

Mastering the Art of Injection Molded Parts Production A Comprehensive Tutorial on Techniques and Best Practices