Injection Mold Maker Comparison Analyzing Cost Efficiency and Quality in Different Manufacturing Techniques

In the ever-evolving landscape of manufacturing, selecting the right injection mold maker can significantly impact both cost efficiency and product quality. According to a recent report by Grand View Research, the global injection molding market is projected to reach $441.1 billion by 2025, underscoring its importance across various industries, from automotive to consumer goods. With factors such as material selection, production speed, and design complexity playing crucial roles, businesses are increasingly challenged to find mold makers that not only meet their budgetary constraints but also deliver high-quality outputs. This ultimate guide delves into the comparison of different injection mold makers, analyzing their manufacturing techniques to provide insights that can drive informed decision-making in pursuit of optimal cost-effectiveness without compromising on quality.

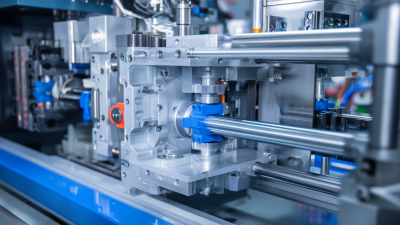

Understanding Injection Molding: Key Concepts and Processes

Injection molding is a widely adopted manufacturing process known for its efficiency and precision. At the heart of this technique lies the injection mold itself, which is a custom-engineered tool designed to produce parts in large quantities. The process begins with the melting of plastic pellets, which are then injected into the mold cavities. This allows for the creation of complex geometries that would be difficult or impossible to achieve with other manufacturing methods. Key concepts such as cycle time, material selection, and mold design are crucial in determining the overall performance and cost efficiency of injection molding.

Understanding the intricacies of injection molding also involves recognizing the various factors that influence quality. Parameters such as injection speed, temperature, and pressure must be meticulously controlled to ensure uniformity and reduce defects. Different manufacturing techniques, including multi-cavity molds and hot runners, can further enhance the production process by minimizing waste and maximizing throughput. By analyzing these aspects, manufacturers can optimize their operations, making informed decisions that balance cost and quality. This comprehensive understanding of injection molding processes is essential for anyone looking to implement or improve their manufacturing strategies.

Comparative Analysis: Cost Structures of Different Injection Mold Techniques

In the injection molding industry, a thorough comparative analysis of cost structures is crucial for optimizing production efficiency and maintaining high-quality standards. Different injection mold techniques, from traditional designs to advanced cooling channel systems, significantly impact both the cost and quality of the final product. For instance, conformal cooling channels (CCCs) have been shown to enhance cooling performance compared to conventional straight-drilled channels, resulting in reduced cycle times and improved dimensional accuracy. This improvement can lead to a potential cost saving of 10-25%, making CCCs a favorable option for manufacturers seeking both efficiency and quality enhancement.

Furthermore, the material choice plays a vital role in cost-effectiveness and product durability. The use of recycled materials, such as rice husks, in injection molding not only lowers material costs but also addresses sustainability challenges in the manufacturing sector. A study highlighted that integrating rice waste into bio-composites can improve mechanical properties while reducing overall expenses. This trend reflects a growing emphasis on eco-friendly practices in manufacturing, prompting companies to adapt their injection molding techniques to meet both economic and environmental objectives. By focusing on these innovative strategies, manufacturers can leverage cost efficiencies while ensuring high-quality output in their production lines.

Quality Control Measures in Injection Mold Manufacturing

Quality control measures in injection mold manufacturing are essential to ensure that the final products meet the required specifications and standards. A robust quality control process begins with the selection of high-quality materials, as even minor flaws in the raw components can lead to significant defects in the molded parts. Implementing stringent supplier evaluation criteria helps manufacturers source the best materials available, establishing a solid foundation for the entire production process.

Once production commences, various inspection methods come into play to maintain consistent quality. These include dimensional checks, visual inspections, and the use of advanced technologies like computer tomography (CT) scanning. Regular monitoring of the injection molding machine settings also plays a crucial role in detecting deviations from standard operating procedures. Furthermore, integrating automated quality control systems can enhance efficiency, enabling real-time data collection and analysis to identify potential issues before they escalate into major problems. Through these measures, injection mold makers not only ensure the durability and functionality of their products but also achieve greater cost efficiency by minimizing waste and rework.

Evaluating Material Choices: Impact on Cost and Product Quality

When comparing injection mold makers, understanding the material choices available is crucial as it significantly impacts both cost efficiency and product quality. Recent trends emphasize the importance of sustainable materials, such as eco-friendly substrates and innovative manufacturing techniques like additive manufacturing. These approaches not only lower the environmental footprint but also enhance the lifecycle performance of products, especially in electronics and packaging industries. For instance, life cycle assessments demonstrate that incorporating recyclable materials can offset the negative effects associated with low-cost devices, ensuring that manufacturers can offer competitive pricing without compromising on sustainability.

Furthermore, the relationship between material selection and consumer perceptions is becoming increasingly important. As consumers grow more conscientious about sustainability, their demands shift towards products made from environmentally friendly materials. This influence is reflected in the purchasing behavior linked to perceived product quality and value. Therefore, injection mold makers must align their material strategies with evolving consumer preferences to enhance customer satisfaction and loyalty. By considering the long-term implications of material choices, manufacturers can achieve a favorable balance between cost efficiency and product excellence, ultimately fostering a more sustainable future in manufacturing.

Future Trends: Innovations in Injection Molding for Enhanced Efficiency

In the realm of injection molding, the future promises transformative innovations aimed at enhancing efficiency and reducing costs. With the advent of advanced technologies such as

machine learning and the Internet of Things (IoT), manufacturers are poised to revolutionize their production processes.

A recent industry report highlights that integrating machine learning algorithms can optimize production lines by up to 30%, significantly decreasing downtime and waste. This is particularly crucial as the

demand for precision and cost-efficiency escalates in competitive markets.

Moreover, the emergence of 5G technology plays a pivotal role in this evolution. By enabling faster data transmission and real-time monitoring, manufacturers can achieve unprecedented levels of operational efficiency.

A report indicates that the implementation of 5G in manufacturing facilities may improve productivity by as much as 20%, as it allows for better connectivity and coordination among machinery. Additionally, the incorporation of

Extended Reality (XR) in the design and testing phases can enhance collaboration and accelerate prototyping, allowing for more innovative designs and quicker time-to-market.

These trends not only signify a shift towards smarter manufacturing but also indicate a future where injection molding becomes increasingly efficient and responsive to market needs.

Related Posts

-

Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques

-

How to Optimize Your Supply Chain for Plastic Manufacturing Success

-

Ultimate Guide to Choosing the Right Injection Machine for Your Manufacturing Needs

-

Global Success of Medical Injection Molding from China Driven by Quality Enhancement