Exploring Injection Molding Tooling Innovations at the 138th Canton Fair 2025 in China

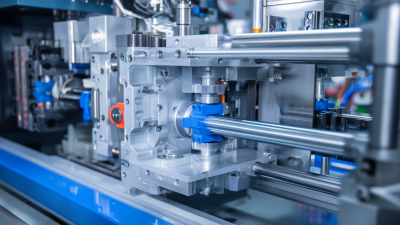

As the manufacturing landscape continues to evolve, the 138th Canton Fair in 2025 stands as a pivotal platform for showcasing cutting-edge innovations in injection molding tooling. This prestigious event, held in China, serves as a premier hub for industry leaders and experts to converge, share insights, and explore the latest trends shaping the future of injection molding technology. With a focus on enhancing production efficiency and material processing capabilities, participants will have the opportunity to witness groundbreaking advancements that are revolutionizing the tooling sector.

From sustainable practices to the integration of smart technologies, the fair will highlight how injection molding tooling is not only addressing current manufacturing challenges but also paving the way for a more resilient and innovative industrial future. The event promises to be an insightful exploration of the synergies between technology and design, fostering collaborations that will drive the industry forward.

Innovative Trends in Injection Molding Tooling Showcased at Canton Fair 2025

The 138th Canton Fair in 2025 is set to be a pivotal platform for showcasing innovative trends in injection molding tooling. As the demand for efficient, high-quality manufacturing processes increases, industry leaders are exploring advancements that enable faster production and enhanced design flexibility. Recent reports indicate that the global injection molding market is estimated to surpass $325 billion by 2027, driven by the expansion of end-user industries such as automotive, packaging, and consumer goods. This trend highlights the urgency for manufacturers to adopt innovative tooling technologies.

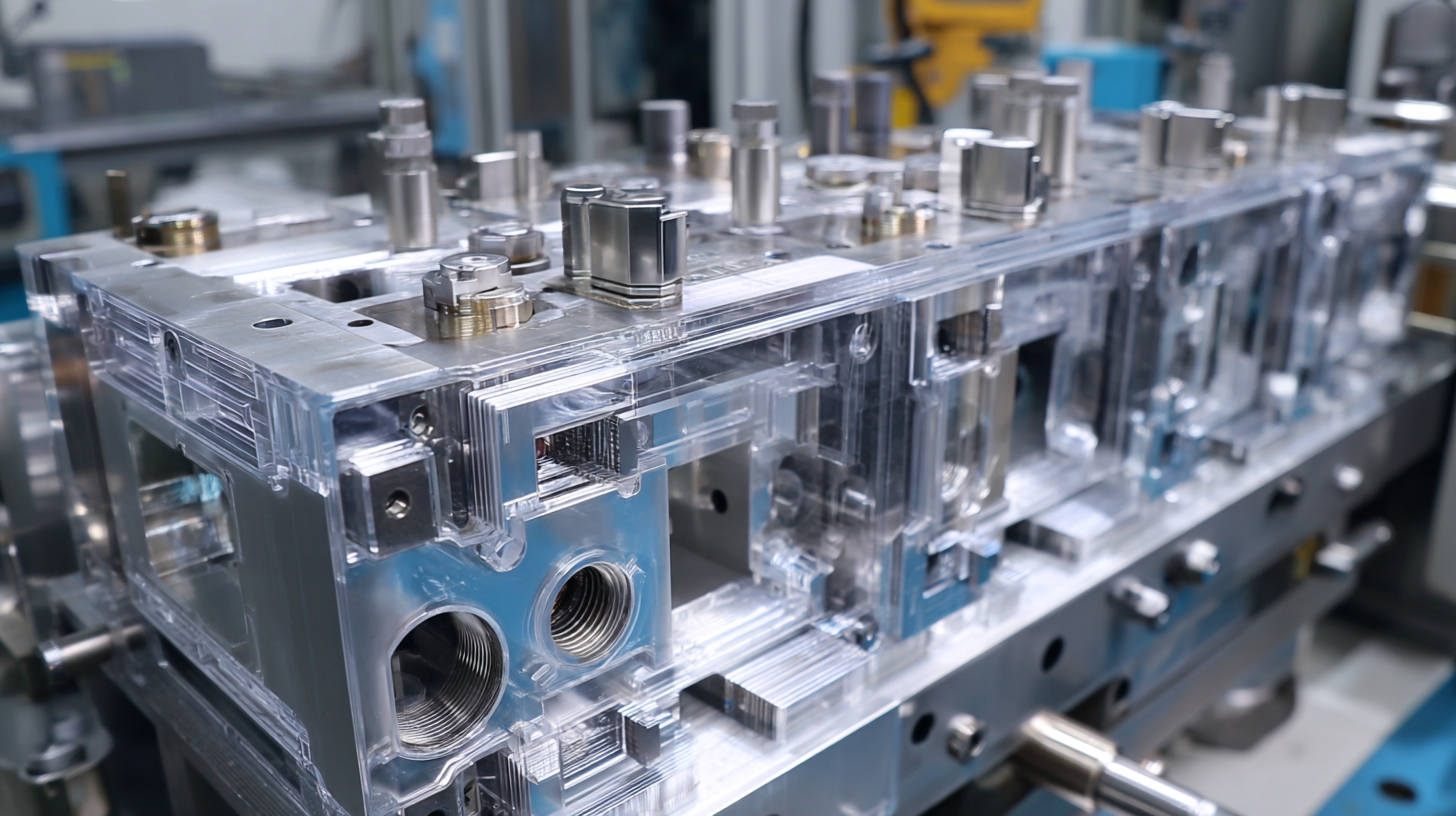

One of the most exciting developments is the application of 3D printing in injection mold tooling, extending beyond traditional uses like conformal cooling. As noted in recent industry observations, 3D printed molds can reduce lead times significantly and allow for the creation of complex geometries that were previously unattainable with conventional methods. Furthermore, the introduction of new materials and techniques, such as CO2-based gas-assist technologies, is set to revolutionize the molding process, maximizing efficiency while minimizing waste. As these innovations are presented at the Canton Fair, attendees will witness firsthand the future of injection molding tooling, which not only promises to meet today's rigorous manufacturing standards but also opens doors to pioneering possibilities in design and production.

Key Exhibitors Leading the Charge in Injection Molding Technologies

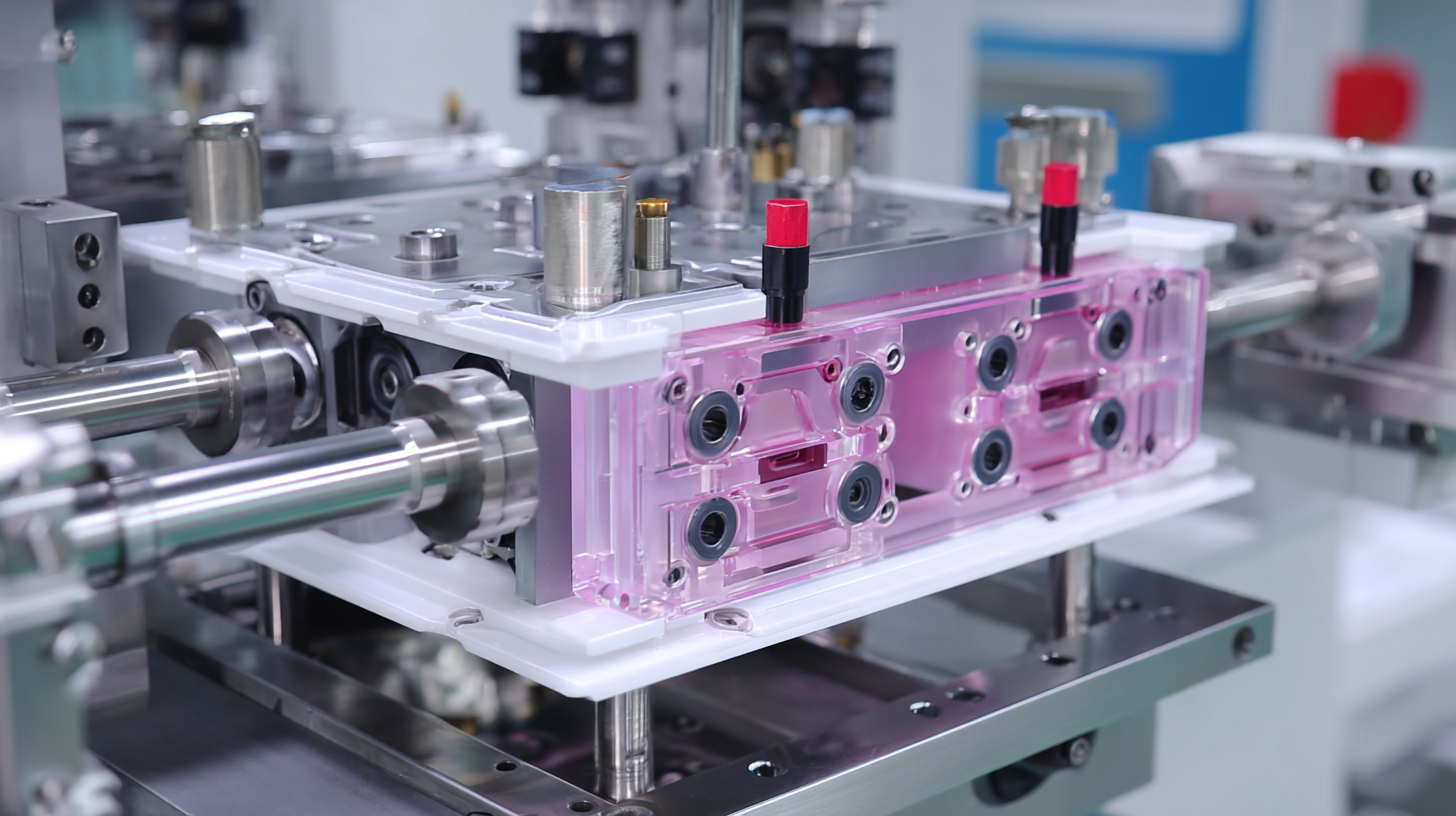

At the upcoming 138th Canton Fair in 2025, key exhibitors are set to showcase groundbreaking innovations in injection molding technology. The fair will serve as a platform for industry leaders to present their latest advancements, focusing on sustainable practices and enhanced efficiency in the manufacturing process. With significant investments in research and development, these companies are poised to drive the future of injection molding, making it more eco-friendly and cost-effective.

Among the notable exhibitors are those pioneering in the development of smart molding solutions that integrate IoT technology, allowing for real-time monitoring and optimization of production. This shift towards intelligent manufacturing not only minimizes waste but also improves product quality and production speed. As the industry embraces these innovations, the Canton Fair will highlight how these advancements are shaping the landscape of plastic manufacturing on a global scale.

Sustainable Practices in Injection Molding Tooling at the 138th Canton Fair

At the 138th Canton Fair in 2025, the spotlight will be on sustainable practices in injection molding tooling, reflecting the industry's commitment to environmental responsibility. As manufacturers increasingly recognize the importance of eco-friendly methodologies, innovative sustainable tooling solutions emerge as key trends. This includes the adoption of biodegradable materials and energy-efficient processes aimed at reducing waste during production. By implementing these practices, companies can minimize their carbon footprint while meeting the rising demand for sustainable products.

Furthermore, advancements in additive manufacturing and digital technologies are transforming traditional injection molding tooling. 3D printing allows for the creation of complex geometries that optimize material usage and enhance product performance. This shift not only supports sustainability but also accelerates the development cycle, enabling faster responses to market needs. Attendees at the Canton Fair will discover how these innovations contribute to a circular economy, demonstrating that efficiency and environmental stewardship can go hand in hand in the injection molding sector.

Networking Opportunities for Industry Professionals at the Canton Fair

The 138th Canton Fair, set to take place in 2025, not only highlights cutting-edge innovations in injection molding tooling but also serves as a pivotal networking platform for industry professionals. According to the Global Injection Molding Market Report, the injection molding sector is expected to reach a valuation of $274 billion by 2026, growing at a CAGR of 4.9%. This growth highlights the increasing importance of networking opportunities at major industry events like the Canton Fair, where professionals can connect, share insights, and explore collaborations that drive innovation and efficiency in this competitive market.

At the Canton Fair, attendees will have the chance to engage with leading manufacturers, suppliers, and technology experts specializing in injection molding tooling. With over 25,000 exhibitors and more than 200,000 visitors expected, the fair provides a unique platform to discover the latest technology advancements, such as sustainable materials and automation in tooling processes. The ability to cultivate relationships with key industry players and gain firsthand knowledge from experts is invaluable for driving future projects and staying ahead in this evolving landscape.

Future Prospects of Injection Molding Tooling in Global Markets

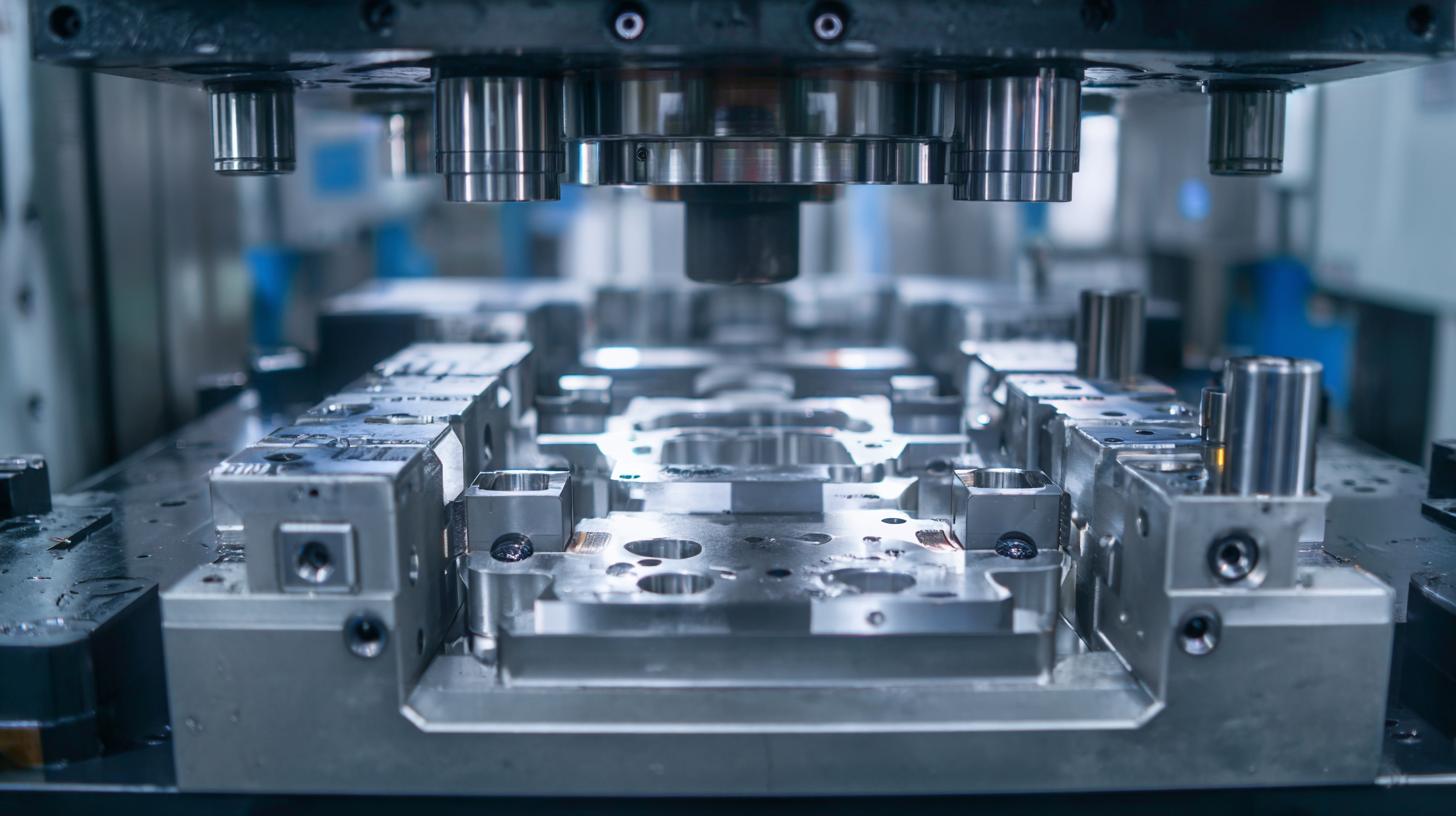

The global plastic injection molding market, valued at $191 billion in 2023, is projected to grow significantly, reaching $235.7 billion by the end of the forecast period. This growth is particularly driven by advancements in tooling innovations and materials that enhance production efficiency and reduce cycle times. As industries increasingly adopt innovative technologies, the market for injection molding tooling is positioned to capitalize on the rising demand for high-quality plastic components across various sectors, including automotive and medical devices.

At the 138th Canton Fair in 2025, these trends will be on full display, showcasing breakthrough technologies such as two-platen injection molding machines and advanced mold release agents. The focus on sustainable materials like polypropylene and ABS will further align with global market needs, emphasizing eco-friendly practices. The future of injection molding tooling not only reinforces its importance in established markets but also opens avenues for growth in emerging economies, enhancing competitiveness in the global landscape.

Exploring Injection Molding Tooling Innovations at the 138th Canton Fair 2025 in China - Future Prospects of Injection Molding Tooling in Global Markets

| Innovation Type | Description | Market Potential | Region of Impact |

|---|---|---|---|

| Automated Tooling Systems | Integration of robotics to streamline the injection molding process. | High growth in efficiency and reductions in labor costs. | Global |

| 3D Printed Mold Components | Using additive manufacturing to create complex mold geometries. | Potential for rapid prototyping and reduced lead times. | North America, Europe |

| Smart Mold Technology | Sensors embedded in molds for real-time monitoring of the process. | Increased process optimization and defect detection. | Asia-Pacific |

| Eco-Friendly Materials | Innovative bioplastics and recycled materials for sustainability. | Growing demand for environmentally conscious products. | Global |

| Enhanced Simulation Software | Advanced modeling tools for predictive analysis and design. | Improved accuracy in mold design leading to cost savings. | Europe, North America |

Related Posts

-

Injection Mold Maker Comparison Analyzing Cost Efficiency and Quality in Different Manufacturing Techniques

-

How to Optimize Your Plastic Injection Molding Process for Maximum Efficiency

-

Global Success of Medical Injection Molding from China Driven by Quality Enhancement

-

Ultimate Guide to Choosing the Right Injection Machine for Your Manufacturing Needs

-

Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques

-

Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape