Mastering the Art of Injection Molded Parts Production A Comprehensive Tutorial on Techniques and Best Practices

In the ever-evolving landscape of manufacturing, injection molded parts remain a cornerstone of production across various industries, including automotive, consumer electronics, and medical devices. According to the latest reports, the global injection molding market is projected to reach USD 310.9 billion by 2027, growing at a CAGR of 3.9% from 2020 to 2027. This significant growth underscores the importance of mastering the art of injection molded parts production.

As manufacturers increasingly seek innovative methods to enhance efficiency, reduce costs, and improve product quality, understanding the nuances of injection molding techniques and best practices has become essential. In this comprehensive tutorial, we will explore the critical aspects of producing high-quality injection molded parts, equipped with insights and strategies that can elevate production capabilities and ensure competitive advantage in this dynamic market.

Benefits of Injection Molding: Cost-Effectiveness and Efficiency in Mass Production

Injection molding stands out as one of the most efficient manufacturing processes for producing parts in bulk. The cost-effectiveness of this technique is primarily driven by its ability to minimize material waste and reduce labor costs. According to a report from the American Society of Plastic Engineers, injection molding can save manufacturers up to 30% in material costs compared to traditional machining methods. This significant reduction can be attributed to the high precision of the molding process, which allows manufacturers to use only the necessary amount of material.

Furthermore, the efficiency of injection molding in mass production is unmatched, with the capability to produce thousands of identical parts in a matter of hours. The Plastics Industry Association noted that a well-optimized injection molding process can achieve cycle times as low as 15 seconds per part, depending on the complexity and design. This rapid production capability not only accelerates time-to-market but also makes it possible for businesses to meet rising consumer demands without compromising on quality. Through the use of advanced technologies such as multi-cavity molds and automation, manufacturers can enhance productivity while maintaining consistency in their output.

Enhanced Design Flexibility: Innovations in Polymer Materials and Tooling Techniques

The evolution of polymer materials and tooling techniques has significantly enhanced design flexibility in injection molded parts production. With advancements in high-performance polymers, manufacturers can achieve superior mechanical properties and thermal resistance, which are critical for various industries, including automotive and medical devices. According to a recent report by MarketsandMarkets, the global engineering plastics market is expected to reach $141.27 billion by 2026, demonstrating the increasing demand for these innovative materials that allow for more intricate designs and efficient production processes.

Moreover, cutting-edge tooling techniques, such as 3D printing for mold production and the use of conformal cooling channels, are revolutionizing traditional manufacturing approaches. A study by Wohlers Associates highlights that 3D printing contributes to a 25-50% reduction in lead times and increases design complexity without significantly raising costs. These innovations not only speed up the prototyping phase but also enable the creation of molds that were previously unfeasible, thus providing designers with a broader creative palette for their injection molded parts. As the industry continues to innovate, the integration of advanced materials and tooling techniques is set to redefine the landscape of injection molding.

Quality and Precision: How Injection Molding Achieves Tight Tolerances in Fabrication

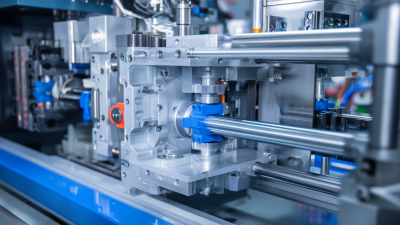

Injection molding is a key technique in modern manufacturing, renowned for its ability to produce high-quality parts with exceptional precision. The process begins with meticulous design and material selection, which play critical roles in achieving tight tolerances. Techniques such as optimizing mold flow, controlling temperature, and maintaining consistent pressure all contribute to minimizing defects and enhancing accuracy in molded components.

To ensure the best results, consider these tips for achieving precision in injection molded parts. First, invest in high-quality molds made from durable materials, as they can withstand repeated use while maintaining their integrity. Second, thorough pre-molding testing—such as flow analysis—can help identify potential issues in the design phase, allowing for adjustments before actual production begins. Lastly, maintaining consistent environmental conditions and equipment calibration during the injection molding process will further enhance the fidelity of the final product.

Moreover, it's vital to implement a robust quality control system throughout the production line. Regular inspections and measurements can catch deviations from specifications early, ensuring that every part meets the stringent standards required for tight tolerances. By adhering to these best practices, manufacturers can master the art of injection molding and deliver precision-engineered components their clients demand.

Mastering the Art of Injection Molded Parts Production

| Technique | Applications | Tolerances | Material Types | Advantages |

|---|---|---|---|---|

| Cold Runner System | Automotive Components | ±0.05 mm | ABS, Polycarbonate | Low material waste |

| Hot Runner System | Medical Devices | ±0.01 mm | PP, PE | Faster cycle times |

| Two-shot Molding | Consumer Products | ±0.03 mm | Various Thermoplastics | Improved aesthetics |

| Insert Molding | Electrical Components | ±0.05 mm | Nylon, Steel | Enhanced strength |

| Micro Molding | Sensor Components | ±0.01 mm | LCP, PEEK | Precision manufacturing |

Sustainability in Injection Molding: Reducing Waste and Energy Consumption Strategies

Sustainability in the injection molding process has become a focal point for manufacturers seeking to minimize environmental impact while maximizing efficiency. By implementing strategies focused on reducing waste and energy consumption, companies can significantly contribute to a circular economy. Material flow analysis plays a crucial role in this transformation, allowing for the identification of opportunities to optimize resource use and enhance the circularity potential of new bio-materials. This analysis helps in understanding the life cycle of materials, identifying areas where waste can be minimized, and ensuring that resources are recycled and reused effectively.

Transitioning to bio-based materials not only aids in reducing carbon footprints but also supports sustainable production practices. By embracing materials that are derived from renewable resources, manufacturers can lower their dependence on fossil fuels and decrease greenhouse gas emissions associated with traditional plastics. Moreover, incorporating sustainable practices into the injection molding process, such as energy-efficient machinery and waste recovery systems, can further enhance the environmental performance of the production line. The collaborative effort towards sustainability will not only benefit the planet but also foster innovation and competitiveness in the industry.

Market Demand Insights: The Growing Need for Custom Injection Molded Components in Various Industries

The demand for custom injection molded components is surging across various industries, driven by the increasing need for precision, efficiency, and adaptability in production processes. Industries such as automotive, healthcare, and consumer goods are continuously seeking tailored solutions to meet specific requirements, pushing the boundaries of traditional manufacturing. As businesses prioritize product innovation and customization, injection molding has emerged as a key technology that offers versatility in design and material selection.

Moreover, the rise of sustainable practices has influenced market demand for injection molded parts. Companies are now focusing on eco-friendly materials and processes that reduce waste and carbon footprint. This shift not only aligns with global sustainability goals but also attracts eco-conscious consumers, creating a competitive edge in the market. As manufacturers refine their techniques and optimize production workflows, the capacity to produce high-quality, custom components at scale becomes more attainable, opening new avenues for growth and collaboration across different sectors.

Related Posts

-

Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques

-

10 Reasons Rapid Injection Molding is the Best Choice for Your Production Needs

-

5 Essential Tips for Sourcing Small Run Plastic Injection Molding: A Global Buyer’s Guide

-

Global Success of Medical Injection Molding from China Driven by Quality Enhancement

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

The Definitive Ultimate Guide to Sourcing the Perfect Injection Machine for Your Business Needs