Ultimate Guide to Mastering Plastic Molding Techniques for Your Business

In the fast-paced world of manufacturing, mastering plastic molding techniques can be a game changer for your business. As industries increasingly rely on plastic components for their durability, versatility, and cost-effectiveness, it becomes imperative to understand the intricacies of the plastic molding process. This ultimate guide will delve into various plastic molding methods, exploring everything from injection molding to blow molding, and providing insights into best practices that can enhance production efficiency and product quality. Whether you are a seasoned professional or a newcomer to the industry, the knowledge shared in this guide will equip you with the tools necessary to optimize your plastic molding strategies, ensuring your business stays competitive in a rapidly evolving market. Prepare to transform your approach to plastic molding and unlock new opportunities for innovation and growth.

In the fast-paced world of manufacturing, mastering plastic molding techniques can be a game changer for your business. As industries increasingly rely on plastic components for their durability, versatility, and cost-effectiveness, it becomes imperative to understand the intricacies of the plastic molding process. This ultimate guide will delve into various plastic molding methods, exploring everything from injection molding to blow molding, and providing insights into best practices that can enhance production efficiency and product quality. Whether you are a seasoned professional or a newcomer to the industry, the knowledge shared in this guide will equip you with the tools necessary to optimize your plastic molding strategies, ensuring your business stays competitive in a rapidly evolving market. Prepare to transform your approach to plastic molding and unlock new opportunities for innovation and growth.

Essential Plastic Molding Techniques Every Business Should Know

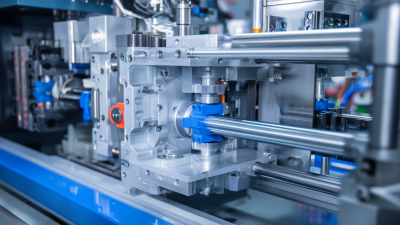

Mastering essential plastic molding techniques is crucial for businesses aiming to enhance efficiency and sustainability in their operations. One of the key techniques is injection molding, which allows manufacturers to produce high-volume parts with precision. Businesses can achieve greater value by optimizing their injection molding processes, reducing waste and labor costs, and focusing on continuous improvement methods. Employing advanced technologies and machinery will enable companies to stay competitive in a market that is projected to grow significantly in the coming years.

Additionally, companies should explore sustainable alternatives, such as bioplastics derived from renewable resources, that can serve as effective replacements for conventional plastics in food packaging. These materials not only minimize environmental impact but also align with the increasing consumer demand for eco-friendly products. It is essential for businesses to adapt and innovate by integrating these sustainable practices into their production lines, thereby fostering a circular plastics economy. By understanding and implementing these essential plastic molding techniques, businesses can position themselves for long-term growth while making a positive impact on the environment.

Key Factors to Consider When Choosing Plastic Materials for Molding

When it comes to mastering plastic molding techniques for your business, one of the key factors to consider is the choice of plastic materials. With the market for LIM (Liquid Silicone Rubber) and LSR (Liquid Silicone Rubber) injection molding projected to grow from $159.5 million in 2024 to $283.83 million by 2032 at a CAGR of 7.47%, understanding the material properties is crucial. Different applications demand specific qualities, such as heat resistance, flexibility, or biocompatibility. For instance, in the development of halogen-free DDR4 memory module connectors, strict adherence to JEDEC and IEC standards guides material selection. This ensures safety and reliability in performance as electronic components grow increasingly complex.

The rise of humanoid robots also presents unique challenges and opportunities in plastic material selection. As these robots become integral to various industries, the demand for durable, lightweight, and environmentally friendly materials increases. Materials like PPSU (polyphenylsulfone) are gaining attention due to their superior mechanical properties and thermal resistance, making them ideal for injection molding applications in these advanced technologies. With a growing number of suppliers entering the market, it's essential for businesses to evaluate their options carefully to find the best-suited materials for their specific needs.

Top Tips for Optimizing Your Plastic Molding Production Process

Mastering plastic molding production processes is crucial for businesses looking to enhance efficiency and optimize output. To achieve this, companies should focus on several key areas. First, investing in advanced plastic processing machinery can significantly improve production speed and accuracy. As highlighted by industry trends, the global plastic processing machinery market is anticipated to grow steadily, indicating a shift towards more automated and sophisticated technologies that can streamline operations.

Additionally, businesses must prioritize the adoption of sustainable materials and practices in their molding processes. The growing demand for environmentally friendly products aligns with the global trend towards sustainability, and incorporating recyclable materials can not only minimize environmental impact but also attract eco-conscious consumers. Embracing innovative techniques, such as high-pressure die-casting and integrated molding systems, can further enhance production efficiency while meeting stringent regulatory standards on sustainability.

Ultimately, by refining their production processes with the latest technology and sustainable practices, companies in the plastic molding sector can secure a competitive edge and adapt to the evolving market landscape. The emphasis on optimizing production not only ensures better resource management but also fosters innovation that caters to the future demands of consumers and industries alike.

Common Mistakes in Plastic Molding and How to Avoid Them

Plastic molding is a crucial process in manufacturing that can significantly impact the quality and efficiency of production. However, many businesses face common pitfalls that can lead to costly setbacks. One frequent mistake is neglecting the importance of material selection. Choosing the wrong type of plastic can weaken the final product, affect its durability, and lead to increased production costs. To avoid this, businesses should conduct thorough research and testing on various plastic materials to determine the best fit for their specific applications.

Another common error is improper mold design. A poorly designed mold can result in defects, such as air traps or uneven wall thickness, which compromise the integrity of the molded parts. It is essential to invest time in creating a well-thought-out mold design that considers factors like cooling efficiency and material flow. Collaborating with experienced mold designers and utilizing simulation software can help identify potential issues early in the design process, ultimately saving time and resources during production. By addressing these common mistakes, businesses can enhance their plastic molding processes and achieve better results.

Ultimate Guide to Mastering Plastic Molding Techniques for Your Business - Common Mistakes in Plastic Molding and How to Avoid Them

| Mistake | Description | Consequences | Prevention Strategies |

|---|---|---|---|

| Incorrect Material Selection | Choosing an inappropriate plastic type for the desired application. | Reduced product durability and performance. | Conduct thorough material research based on project requirements. |

| Improper Mold Design | Mold designs lacking necessary features or that are too complex. | Increased production time and costs. | Work with experienced engineers to optimize mold designs. |

| Inadequate Design Validation | Failing to prototype or test designs before mass production. | Higher likelihood of product recalls and rework. | Implement thorough testing procedures early in the design phase. |

| Ignoring Injection Molding Parameters | Overlooking key parameters like temperature and pressure settings. | Poor surface finish and dimensional inaccuracies. | Regularly review and adjust settings based on materials used. |

| Neglecting Maintenance | Failing to maintain machinery and molds. | Higher frequency of breakdowns and delays. | Establish a regular maintenance schedule and adhere to it. |

Innovative Trends in Plastic Molding Technology You Should Follow

The world of plastic molding technology is rapidly evolving, introducing innovative trends that businesses must keep track of to stay competitive. One significant trend is the rise of 3D printing in the molding process. This technology allows for the rapid prototyping of complex designs, reducing the time and cost associated with traditional molding methods. Companies are increasingly utilizing 3D printing to create tailored molds that can produce customized products, enhancing flexibility and responsiveness to market demands.

Another pivotal advancement is the integration of smart technology into plastic molding. The adoption of Internet of Things (IoT) devices in manufacturing processes empowers businesses with real-time data analysis and monitoring. This not only streamlines production but also optimizes resource usage and minimizes waste. Additionally, advancements in materials technology, such as biodegradable plastics and high-performance polymers, are transforming the industry. Embracing these trends enables businesses to innovate their product offerings and align with sustainability goals, ultimately driving growth and consumer loyalty in a more environmentally-conscious market.

Related Posts

-

Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques

-

10 Reasons Rapid Injection Molding is the Best Choice for Your Production Needs

-

Mastering the Art of Injection Molded Parts Production A Comprehensive Tutorial on Techniques and Best Practices

-

Global Success of Medical Injection Molding from China Driven by Quality Enhancement

-

Ultimate Guide to Choosing the Right Injection Machine for Your Manufacturing Needs

-

How to Optimize Your Supply Chain for Plastic Manufacturing Success