How to Maximize Efficiency in Small Volume Injection Molding: Industry Insights and Best Practices

In the rapidly evolving landscape of manufacturing, small volume injection molding has emerged as a critical process for companies seeking to optimize production efficiency while maintaining quality. According to a recent report by Smithers Pira, the global market for injection molded plastics is expected to reach approximately $400 billion by 2025, with small volume applications increasingly gaining traction due to the rise of customized products and short production runs. This trend highlights the importance of adopting best practices and innovative strategies tailored to small volume injection molding.

By leveraging advanced technologies and streamlining operations, manufacturers can significantly enhance productivity, reduce waste, and respond quickly to market demands. This article delves into industry insights and effective methodologies that can help businesses maximize efficiency in small volume injection molding, ultimately positioning them for success in a competitive marketplace.

By leveraging advanced technologies and streamlining operations, manufacturers can significantly enhance productivity, reduce waste, and respond quickly to market demands. This article delves into industry insights and effective methodologies that can help businesses maximize efficiency in small volume injection molding, ultimately positioning them for success in a competitive marketplace.

Identifying Key Factors for Efficiency in Small Volume Injection Molding

Efficiency in small volume injection molding can be significantly enhanced by pinpointing key factors that influence the process. One of the foremost elements is the choice of materials, as the right polymer can ensure quicker cycle times and better quality in the final product. Additionally, incorporating advanced technologies, such as injection molding simulation software, allows manufacturers to optimize their mold designs and process parameters, ultimately reducing waste and improving turnaround times.

Moreover, integrating practices from other manufacturing advancements, like those seen in the metal additive manufacturing sector, can provide valuable insights. For instance, utilizing rapid prototyping techniques can not only streamline production but also facilitate the creation of more complex and intricate mold designs that are often unattainable through traditional methods.

Emphasizing continuous improvement and adapting to new technologies will further empower companies to maximize their efficiency in small volume injection molding while maintaining high standards in output quality.

Selecting the Right Materials for Maximum Production Efficiency

When it comes to small volume injection molding, selecting the right materials is crucial for maximizing production efficiency. The choice of materials directly impacts the mold's performance, cycle time, and overall production costs. Engineers should consider properties such as melt flow index, thermal stability, and compatibility with the injection molding process. For instance, using materials with a high melt flow can lead to faster filling times, significantly reducing cycle durations. However, it is also essential to balance these properties with the end-use requirements of the molded parts.

Another important factor is the recycling and sustainability of the chosen materials. Opting for recyclable thermoplastics can not only enhance production efficiency but also contribute to environmentally friendly practices in manufacturing. The right material selection should also take into account the potential for secondary operations, like painting or assembly, which can further streamline the production process. Therefore, collaboration between material suppliers and manufacturers is vital to identify materials that not only meet performance standards but also facilitate efficient production workflows.

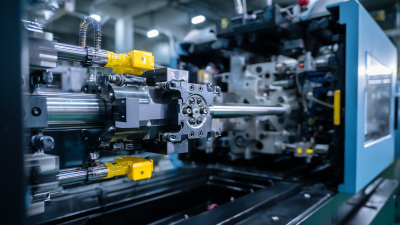

Optimizing Machine Settings for Enhanced Performance

Optimizing machine settings is crucial for enhancing performance in small volume injection molding. The key to achieving optimal results lies in fine-tuning parameters such as temperature, pressure, and cycle time. Keeping the melt temperature within the recommended range ensures that the material flows adequately while minimizing defects. Additionally, adjusting injection speed and pressure can significantly impact the quality of the molded parts, leading to fewer errors and an overall smoother production process.

Optimizing machine settings is crucial for enhancing performance in small volume injection molding. The key to achieving optimal results lies in fine-tuning parameters such as temperature, pressure, and cycle time. Keeping the melt temperature within the recommended range ensures that the material flows adequately while minimizing defects. Additionally, adjusting injection speed and pressure can significantly impact the quality of the molded parts, leading to fewer errors and an overall smoother production process.

Tips for optimizing settings include closely monitoring the cooling time, as an efficient cooling cycle can prevent warping and improve dimensional accuracy. It’s also advisable to conduct regular maintenance checks to keep machinery running at peak efficiency. Adjusting to the specific characteristics of the material used, such as viscosity and thermal properties, can further enhance performance.

Another important aspect is the calibration of ejection settings, which should be synchronized with the cooling process. If the parts are ejected too early, it may result in deformities; too late, and you risk damaging them. By meticulously adjusting these parameters, manufacturers can ensure consistent quality and reduced waste, ultimately maximizing the efficiency of their small volume injection molding operations.

Streamlining the Injection Molding Process to Reduce Cycle Time

Maximizing efficiency in small volume injection molding while streamlining production processes can significantly reduce cycle times. Implementing advanced temperature control technologies is crucial for achieving consistent product quality, as it directly influences the cooling and solidification phase of the injection molding process. Recent industry insights suggest that manufacturers leveraging optimized temperature management can enhance cycle time efficiency by over 20%. This improvement is vital, especially as the global injection molding machine market is projected to exceed USD 10.4 billion by 2024, with a growth rate of 4.8% annually from 2025 to 2034.

Moreover, the integration of hybrid manufacturing technologies is revolutionizing the injection molding landscape. By combining additive manufacturing with traditional techniques, companies can produce parts with improved speed and flexibility. Such hybrid machines are becoming increasingly popular, allowing for more complex designs while maintaining high-quality standards. Incorporating artificial intelligence into these processes can further streamline operations by optimizing production parameters and predictive maintenance, ensuring that manufacturers remain competitive in a rapidly evolving market.

Maximizing Efficiency in Small Volume Injection Molding

Implementing Quality Control Practices for Consistent Results

Implementing quality control practices in small volume injection molding is crucial for achieving consistent and reliable results. Quality control begins with rigorous material selection, ensuring that the raw materials used meet the necessary specifications and standards. This foundational step minimizes defects during the molding process and enhances the overall quality of the final product. Regular audits of materials can further ensure that suppliers adhere to quality benchmarks, helping to maintain the integrity of production.

In addition to material selection, monitoring the injection molding process itself is vital. Employing techniques such as statistical process control (SPC) enables manufacturers to track key parameters, such as temperature and pressure, in real-time. This proactive monitoring allows for immediate adjustments, reducing the likelihood of defects. Furthermore, implementing regular maintenance schedules for machinery can prevent breakdowns that could compromise quality. By embracing these quality control practices, companies not only enhance product consistency but also build a reputation for reliability in the competitive landscape of injection molding.

Related Posts

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

Ultimate Guide to Choosing the Right Injection Machine for Your Manufacturing Needs

-

Injection Mold Maker Comparison Analyzing Cost Efficiency and Quality in Different Manufacturing Techniques

-

The Definitive Ultimate Guide to Sourcing the Perfect Injection Machine for Your Business Needs

-

Ultimate Guide to Small Run Plastic Injection Molding for Global Buyers

-

Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape