How to Optimize Your Plastic Injection Molding Process for Maximum Efficiency

In the ever-evolving landscape of manufacturing, optimizing the plastic injection molding process has become pivotal for companies striving to enhance productivity and reduce costs. According to a report from Grand View Research, the global plastic injection molding market is anticipated to reach USD 451.9 billion by 2027, growing at a CAGR of 5.6% during the forecast period. This growth underscores the importance of efficiency in production methods to stay competitive. Inefficiencies in the injection molding process can lead to increased cycle times and material waste, which directly impact profitability. By implementing strategic practices such as advanced simulation software, effective maintenance schedules, and energy-efficient machinery, organizations can significantly improve their operational efficiency. This blog will explore actionable strategies to streamline your plastic injection molding process for maximum efficiency, ensuring that manufacturers not only meet the increasing demand but also achieve sustainable growth.

Identifying Key Factors Affecting Injection Molding Efficiency

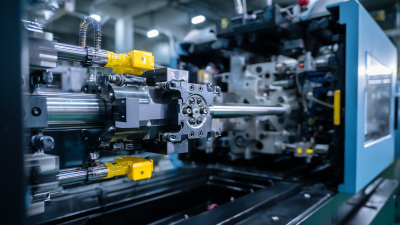

When optimizing your plastic injection molding process for maximum efficiency, it is crucial to identify the key factors that affect the overall performance. One of the primary elements is the machine settings. Proper calibration of temperature, pressure, and injection speed can greatly influence cycle times and product quality. Adjusting these parameters according to the specific material and design can help achieve a more consistent output and minimize defects.

Another critical factor is the choice of materials. Different polymers have unique flow characteristics and thermal properties that can impact the molding process. Selecting the right resin not only enhances product performance but can also reduce cycle times. Moreover, incorporating additives or modifying the material formulation can improve flow and cooling, which streamlines the entire operation.

Lastly, tooling design plays a pivotal role in molding efficiency. Optimizing mold design with features such as optimized cooling channels and proper venting can significantly reduce cycle times. Investing in high-quality molds, combined with regular maintenance, ensures reliability and minimizes downtime. By addressing these key factors, manufacturers can enhance their injection molding processes, leading to improved productivity and cost savings.

Analyzing Material Selection for Optimal Performance

Selecting the right materials is crucial for optimizing the performance of your plastic injection molding process. In recent studies, the significance of material properties has been emphasized, showing that the specific characteristics of chosen materials can greatly impact the efficiency and effectiveness of the entire molding operation. For instance, understanding the thermal and mechanical properties of various polymers can lead to better cycle times and finished part quality.

Tips: To enhance your material selection, conduct a thorough analysis of the intended application and operational conditions. Utilize advanced simulation tools to predict how different materials will behave under various stress and temperature conditions. This approach mirrors the findings from recent research where the performance of composite materials was optimized by considering their mechanical properties.

Moreover, continual material evaluation can lead to innovations that enhance product durability and reduce production time. For example, incorporating nanocomposites into your material selection can drastically improve thermal efficiency, reflecting trends observed in energy-related efficiency studies. By staying informed about recent advancements in material technology, you can ensure that your injection molding process remains competitive and efficient.

Implementing Advanced Technology and Automation Solutions

In today’s competitive manufacturing landscape, the integration of advanced technology and automation solutions in plastic injection molding is crucial for enhancing efficiency and productivity. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $369.2 billion by 2026, driven largely by innovations in automation and smart manufacturing technologies. By adopting these advancements, manufacturers can significantly reduce cycle times, minimize material waste, and achieve higher precision in production.

Implementing automation solutions, such as robotic arms and AI-driven monitoring systems, can streamline the molding process. A study by Allied Market Research indicates that automated injection molding processes can increase production efficiency by up to 30%. Real-time data analytics allows manufacturers to monitor machine performance continuously, leading to proactive maintenance that reduces downtime. Additionally, advanced technology such as Industry 4.0 enables seamless integration of the injection molding process with other production stages, promoting a more cohesive and agile manufacturing environment. As the industry evolves, companies that prioritize these innovations will not only optimize their operations but also position themselves as leaders in the market.

Streamlining Workflow: Best Practices for Process Management

In today's fast-paced manufacturing environment, optimizing the plastic injection molding process is crucial for enhancing overall efficiency. By implementing best practices in workflow management, companies can significantly reduce lead times and operational costs. Studies indicate that organizations adopting advanced project management tools can improve their productivity by up to 30%. These tools facilitate better communication among teams, allowing for real-time adjustments and efficient handling of issues as they arise.

Furthermore, automating repetitive tasks through project management software not only streamlines workflows but also minimizes human error, leading to higher quality outputs. For instance, companies that integrate AI-driven analytics into their injection molding processes report an up to 25% increase in production rates. As manufacturers look ahead to 2025, investing in state-of-the-art project management and process optimization tools will not only keep them competitive but will also create a more agile production environment, driving growth and innovation in the industry.

Regular Maintenance and Troubleshooting for Consistent Output

Regular maintenance is crucial for ensuring a consistent output in plastic injection molding processes. Keeping machinery in optimal condition not only extends the life of the equipment but also minimizes the risk of interruptions that can lead to production delays. A well-structured maintenance schedule should include routine inspections, lubrication, and necessary repairs to parts that show signs of wear. By addressing potential issues before they escalate, manufacturers can maintain a steady workflow and avoid costly downtime, which is essential for maximizing efficiency.

In addition to routine maintenance, effective troubleshooting is key to managing unexpected challenges that may arise during production. Operators should be trained to identify common symptoms of machine malfunctions, such as unusual noises, fluctuations in temperature, or inconsistencies in output quality. Implementing a proactive approach to troubleshooting enables teams to quickly diagnose and resolve issues, ensuring that production remains on track. Moreover, documenting these troubleshooting processes can serve as a valuable knowledge base for future reference, fostering continuous improvement in the injection molding workflow.

Optimization of Plastic Injection Molding Process

Related Posts

-

Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape

-

5 Essential Tips for Sourcing Small Run Plastic Injection Molding: A Global Buyer’s Guide

-

Ultimate Guide to Small Run Plastic Injection Molding for Global Buyers

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

Mastering the Art of Injection Molded Parts Production A Comprehensive Tutorial on Techniques and Best Practices

-

The Definitive Ultimate Guide to Sourcing the Perfect Injection Machine for Your Business Needs