Why Plastic Injection Molding is Essential for Modern Manufacturing Success

In the fast-evolving landscape of modern manufacturing, the significance of plastic injection molding cannot be overstated. As industries strive for efficiency and innovation, this process emerges as a cornerstone, enabling the production of complex and precise components in various sectors. Renowned expert in the plastic injection field, Dr. Emily Carter, has often emphasized the role of this technology in streamlining manufacturing operations. She once stated, "Plastic injection molding not only enhances productivity but also opens doors to creative designs that drive product innovation."

The ability to produce high volumes of identical parts with remarkable accuracy positions plastic injection molding as a vital resource for manufacturers. This methodology not only reduces waste but also allows for the rapid iteration of design elements, making it indispensable in a competitive market. As we delve deeper into the intricacies of plastic injection molding, we will explore its advantages, applications, and the future it holds in shaping manufacturing success across diverse industries.

The Role of Plastic Injection Molding in Manufacturing Efficiency

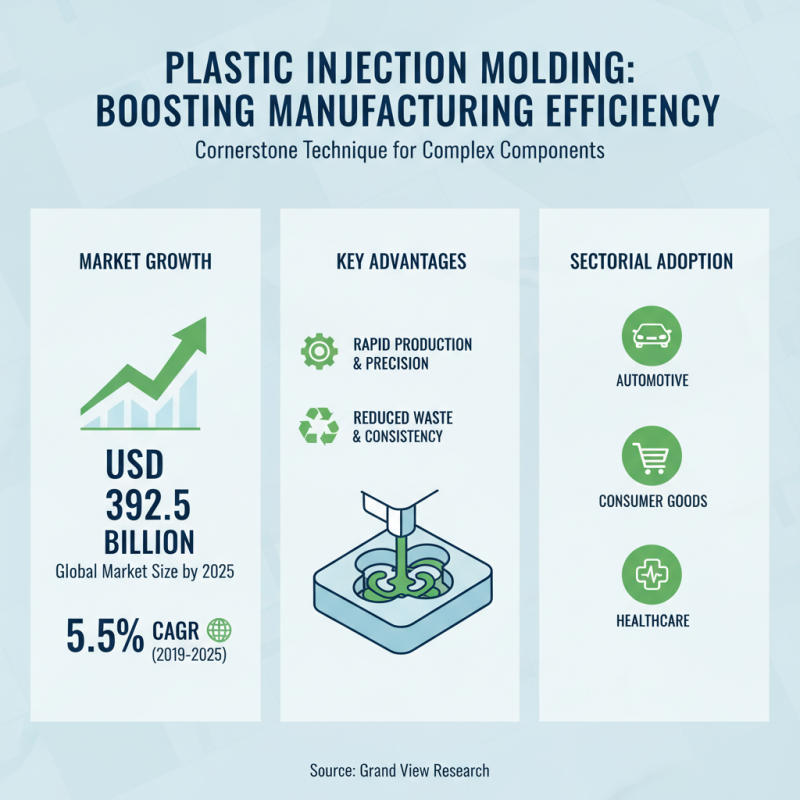

Plastic injection molding plays a pivotal role in enhancing manufacturing efficiency, being a cornerstone technique in the production of complex plastic components. According to market research conducted by Grand View Research, the global plastic injection molding market size is expected to reach USD 392.5 billion by 2025, growing at a CAGR of 5.5%. This growth emphasizes the increasing reliance on this technology in various sectors, including automotive, consumer goods, and healthcare. The rapid production capabilities and precision offered by injection molding processes allow manufacturers to produce large volumes of parts with intricate designs, ensuring consistency and reducing waste.

Furthermore, studies indicate that injection molding significantly minimizes cycle times, which is crucial for meeting the demands of modern manufacturing. The average cycle time for injection molding can be as low as 10-30 seconds depending on the part complexity. This efficiency not only speeds up production but also reduces labor and operational costs. A report by the Society of Plastics Engineers highlights that adopting advanced injection molding techniques can lead to a reduction in energy consumption by up to 50%, further enhancing cost-effectiveness in production processes. As manufacturers strive for sustainability while maintaining rapid output, plastic injection molding proves to be an indispensable asset in optimizing manufacturing efficiency.

Key Advantages of Plastic Injection Molding over Traditional Methods

Plastic injection molding has become a cornerstone of modern manufacturing due to its numerous advantages over traditional methods. One of the primary benefits is the ability to produce complex geometries with high precision. Unlike older techniques such as manual assembly or machining, injection molding allows for intricate designs that would be difficult or impossible to achieve otherwise. This precision not only enhances the aesthetic appeal of products but also ensures consistency across production runs, significantly reducing the likelihood of defects.

Furthermore, plastic injection molding is incredibly efficient in terms of production speed. Once the mold is created, the process can produce large volumes of parts in a fraction of the time required by traditional methods. This efficiency translates to lower labor costs and quicker turnaround times, allowing manufacturers to respond rapidly to market demands. Additionally, the process is highly scalable, making it easier for businesses to adjust their production levels without compromising quality. As a result, companies can achieve greater flexibility and adaptability, positioning themselves for success in a competitive marketplace.

Applications of Plastic Injection Molding in Various Industries

Plastic injection molding plays a crucial role in various industries due to its efficiency and versatility. This manufacturing process is employed in sectors such as automotive, healthcare, consumer goods, and electronics. For instance, according to a report by Research and Markets, the global automotive plastic components market alone is expected to reach USD 41.25 billion by 2025, largely driven by the increased use of lightweight materials that are consistent with injection molding techniques. This trend highlights how critical injection molding is for producing essential components such as dashboards, bumpers, and interior fixtures that meet safety and performance standards.

In the healthcare industry, the demand for precision-engineered medical devices has surged. The plastic injection molding process allows for the creation of intricate designs and patterns necessary for medical tools and devices. A study by Grand View Research indicates that the global medical plastics market is projected to reach USD 27.85 billion by 2025, illustrating the importance of injection molding in producing everything from syringes to surgical equipment. The ability to rapidly produce high-quality, sterile plastic components makes injection molding indispensable in ensuring that healthcare devices are both reliable and cost-effective, ultimately improving patient safety and outcomes.

Technological Advances in Plastic Injection Molding Processes

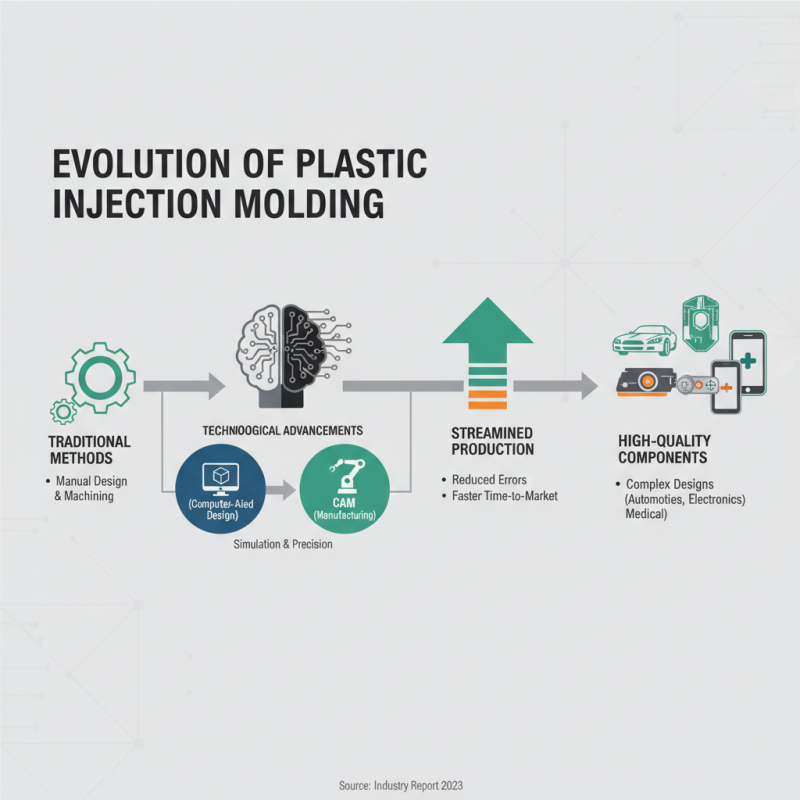

The evolution of plastic injection molding processes has been driven by significant technological advancements that have streamlined production and improved efficiency. Innovations such as computer-aided design (CAD) and computer-aided manufacturing (CAM) allow manufacturers to create complex and precise molds with greater speed. These technologies enhance the ability to simulate the molding process, minimizing errors and reducing the time from concept to production. As a result, companies can produce high-quality plastic components with intricate designs that meet stringent specifications, catering to a wide range of industries from automotive to consumer electronics.

Another vital advancement in plastic injection molding is the adoption of Industry 4.0 technologies, including automation and data analytics. Smart factories utilize connected equipment and real-time data monitoring to optimize production workflows and resource management. This integration of IoT devices facilitates predictive maintenance and quality control, ensuring that machinery operates at peak efficiency and producing fewer defects. Consequently, manufacturers can adapt quickly to changing market demands, scaling production up or down with ease while maintaining consistency in product quality. These technological developments not only enhance the effectiveness of plastic injection molding but also position it as a cornerstone for success in modern manufacturing.

Sustainability and Environmental Considerations in Injection Molding

The rise of environmental awareness has pushed industries to rethink traditional manufacturing processes, making sustainability a crucial aspect of modern plastic injection molding. This method not only allows for the mass production of complex parts but also offers opportunities to reduce waste and improve resource efficiency. By using recycled materials in the injection molding process, manufacturers can significantly lower their carbon footprint while still producing high-quality products. Implementing practices that prioritize sustainability can lead to a competitive edge in the market, where eco-conscious consumers are increasingly making informed choices.

Tips for enhancing sustainability in injection molding include conducting a thorough assessment of raw materials, opting for bio-based plastics, and optimizing production processes to minimize energy use. Additionally, investing in advanced technologies, such as energy-efficient machinery and better molding techniques, can greatly contribute to reducing the environmental impact. Companies should also consider establishing a recycling program for their products to ensure that end-of-life items are repurposed, thus contributing to a circular economy.

By embracing sustainable practices in injection molding, companies not only comply with evolving regulations but also meet consumer demands for environmentally friendly products. This transition is not only beneficial for the planet but also fosters innovation within the manufacturing process, paving the way for a more responsible and successful industry.

Plastic Injection Molding Sustainability Metrics

This chart illustrates the impact of various sustainability metrics related to plastic injection molding. It highlights the percentage reduction in energy consumption, waste generation, and carbon emissions over the last decade, showcasing how modern manufacturing practices contribute to environmental sustainability.

Related Posts

-

Innovative Uses of Plastic Injection Molding in Sustainable Product Design

-

Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape

-

5 Essential Tips for Sourcing Small Run Plastic Injection Molding: A Global Buyer’s Guide

-

The Definitive Ultimate Guide to Sourcing the Perfect Injection Machine for Your Business Needs

-

How to Optimize Your Plastic Injection Molding Process for Maximum Efficiency

-

Exploring Cost Efficiency in Low Cost Injection Molding at 2025 China Import and Export Fair