What is Plastic Manufacturing? Key Processes and Benefits Explained

Plastic manufacturing is a crucial process that plays a vital role in today's industrial landscape. From everyday household items to complex components used in advanced technology, plastics have become an integral part of our lives. This versatile material is not only lightweight and durable but also cost-effective, making it a preferred choice for various applications across multiple industries. Understanding the key processes involved in plastic manufacturing is essential for industries aiming to innovate and improve their production methods.

The plastic manufacturing process encompasses a series of steps designed to transform raw materials into finished products, including molding, extrusion, and thermoforming. Each of these processes offers unique advantages, allowing manufacturers to create items that meet specific requirements for functionality and aesthetics. Additionally, the benefits of plastic manufacturing extend beyond the production phase; the long-lasting nature of plastic products also contributes to sustainability efforts by reducing the need for frequent replacements.

As we delve deeper into the world of plastic manufacturing, we will explore these key processes in detail, highlighting their significance and the benefits they offer. Through this examination, it becomes evident that plastic manufacturing not only supports economic growth but also drives innovation and efficiency in numerous sectors.

What is Plastic Manufacturing?

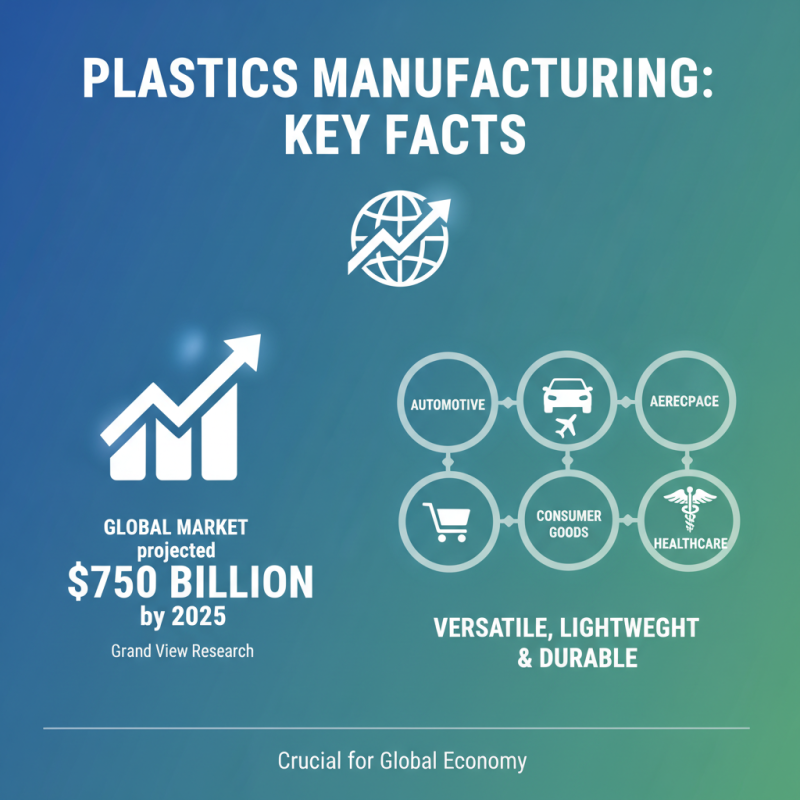

Plastic manufacturing refers to the process of creating plastic products from various raw materials, primarily polymers. This industry plays a crucial role in the global economy, with the plastics market projected to reach approximately $750 billion by 2025, according to a report by Grand View Research. The versatility of plastics, along with their lightweight and durable nature, has made them invaluable across numerous sectors, including automotive, aerospace, consumer goods, and healthcare.

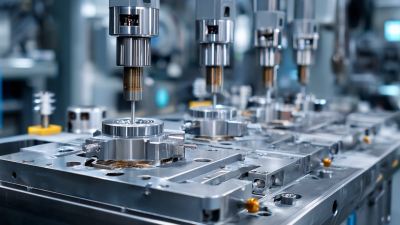

The manufacturing process typically involves several key stages, including melt processing, molding, and extrusion. For instance, injection molding, one of the most popular methods, allows manufacturers to produce complex shapes with high precision and minimal waste. According to a study published by the Plastics Industry Association, injection molding accounts for nearly 30% of all plastic processing in North America. Furthermore, advancements in technology, such as 3D printing and bio-based plastics, are reshaping the manufacturing landscape, offering more sustainable options and improving production efficiency. Overall, the continuous growth of the plastic manufacturing sector is driven by innovation and an increasing demand for versatile materials across various applications.

Primary Materials Used in Plastic Manufacturing

In the realm of plastic manufacturing, the choice of primary materials plays a crucial role in determining the efficiency and quality of the final products. The most commonly used materials include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS). According to the Plastics Industry Association, these polymers dominate the market, with polyethylene accounting for over 30% of global plastic demand, thanks to its versatility and cost-effectiveness in applications ranging from packaging to automotive components.

Additionally, additives are often incorporated into these primary materials to enhance performance attributes. For instance, plasticizers, stabilizers, and fillers can significantly modify the characteristics of plastics, improving their mechanical strength, thermal stability, and resistance to environmental factors. The global market for plastic additives is projected to reach $70 billion by 2025, reflecting the increasing focus on customizing plastic materials to meet specific functional requirements. This trend highlights the importance of selecting the right base materials and additives in achieving desired product specifications in various industrial applications.

Key Processes Involved in Plastic Manufacturing

The key processes involved in plastic manufacturing are crucial for transforming raw materials into the diverse range of plastic products we use daily. The most common method, injection molding, accounts for approximately 32% of the total plastic production globally, according to recent industry reports. This process involves injecting molten plastic into a mold, allowing it to cool and solidify, creating complex shapes efficiently and with high precision. This efficiency not only reduces production time but also minimizes material waste, making it an environmentally advantageous choice in the industry.

Another significant process is extrusion, which plays a vital role in creating continuous shapes such as pipes, sheets, and films. In 2023, the extrusion segment is expected to reach a valuation of over $40 billion, highlighting its importance in sectors ranging from construction to packaging. During extrusion, plastic pellets are heated and forced through a die, resulting in long sections of uniform products. This technique is noted for its flexibility in adapting to various product shapes and sizes, thus driving innovation in plastic applications.

Blow molding is also essential, especially for producing hollow plastic items like bottles and containers. This method involves inflating a heated plastic tube within a mold, creating lightweight and durable products. Reports indicate that the blow molding segment is anticipated to grow at a CAGR of 5% over the next few years, primarily driven by its applications in the beverage and consumer goods markets. Overall, these processes not only enhance productivity but also facilitate the development of sustainable practices within the plastic manufacturing industry.

Benefits of Plastic Manufacturing in Modern Industry

Plastic manufacturing plays a crucial role in modern industry due to its versatility and efficiency. One of the primary benefits of plastic manufacturing is the material's lightweight nature, which can lead to reduced transportation costs and energy consumption. This is especially advantageous in sectors like automotive and aerospace, where every ounce saved can significantly improve fuel efficiency. Additionally, plastics can be molded into intricate shapes, allowing for complex designs that enhance product functionality and aesthetic appeal.

Another notable benefit is the cost-effectiveness of plastic production. The ability to mass-produce plastic items at a lower cost compared to traditional materials such as metal or glass allows companies to remain competitive while maintaining quality. This affordability extends the reach of plastic products across various industries, from packaging and consumer goods to medical devices and construction materials.

Tip 1: When considering plastic for your next project, explore various types of plastics to find the one that best suits your needs, taking into account factors such as durability, flexibility, and thermal resistance.

Tip 2: Always prioritize sustainability by investigating biodegradable or recyclable plastic options. This not only meets growing environmental standards but also appeals to eco-conscious consumers.

Tip 3: Regularly review advancements in plastic manufacturing technologies, as innovations can lead to improved efficiency and opened avenues for product development.

Applications of Plastic Products Across Various Sectors

Plastics have become an integral part of numerous industries due to their versatility, durability, and cost-effectiveness. In the automotive sector, for example, plastic components are widely utilized to reduce vehicle weight, enhance fuel efficiency, and improve safety features. From dashboards to body panels, the application of plastics helps in manufacturing vehicles that meet modern performance and environmental standards. Additionally, the healthcare industry relies heavily on plastic products, including medical devices, syringes, and packaging materials. These plastic items are specifically designed to meet strict hygiene and safety regulations while ensuring that they are lightweight and easy to dispose of or recycle.

Another significant application of plastic products is in the construction industry. Construction materials such as PVC piping, insulation, and siding provide long-lasting performance, resistance to environmental factors, and improved energy efficiency in buildings. Plastics are also used in consumer products, ranging from kitchenware to toys. Their ability to be molded into various shapes and colors allows for endless creativity and design possibilities. With advancements in manufacturing technology, the applications of plastic products continue to expand, addressing the demands of sustainability and functionality in various sectors.

What is Plastic Manufacturing? Key Processes and Benefits Explained - Applications of Plastic Products Across Various Sectors

| Application Sector | Plastic Type | Manufacturing Process | Benefits |

|---|---|---|---|

| Automotive | Polypropylene (PP) | Injection Molding | Lightweight, durable, cost-effective |

| Healthcare | Polyethylene (PE) | Blow Molding | Sterile, flexible, customizable |

| Consumer Goods | Polyvinyl Chloride (PVC) | Thermoforming | Versatile, aesthetic options, easy to assemble |

| Packaging | Polystyrene (PS) | Extrusion | Lightweight, efficient, protects contents |

| Construction | Acrylonitrile Butadiene Styrene (ABS) | 3D Printing | Strong, adaptable, allows for complex designs |

Related Posts

-

Top Plastic Part Manufacturing Techniques You Need to Know

-

The Definitive Ultimate Guide to Sourcing the Perfect Injection Machine for Your Business Needs

-

Revolutionizing Product Development: The Benefits of Rapid Prototype Injection Molding Explained

-

Innovative Uses of Plastic Injection Molding in Sustainable Product Design

-

What is Plastic Molding? Exploring Process Types, Benefits, and Market Trends in 2023

-

Why Plastic Injection Molding is Essential for Modern Manufacturing Success