What is Plastic Molding? Exploring Process Types, Benefits, and Market Trends in 2023

Plastic molding is a crucial manufacturing process in various industries, shaping materials into durable and versatile products. According to a report by MarketsandMarkets, the global plastic molding market is projected to reach USD 650 billion by 2026, driven by an increase in demand for lightweight and customizable components in automotive, consumer goods, and electronics sectors. This rising market trend illustrates the significance of plastic molding as a key player in modern manufacturing.

As industries continue to innovate, understanding the various types of plastic molding processes—including injection molding, blow molding, and rotational molding—becomes essential for businesses aiming to enhance production efficiency and reduce costs. A study conducted by Grand View Research highlights that injection molding alone accounted for over 20% of the total plastic molding market share in 2020, showcasing its prominence and effectiveness in producing high-volume parts with complex geometries.

In 2023, the evolution of plastic molding technologies, along with the incorporation of sustainable practices, is reshaping the landscape of this industry. Manufacturers are increasingly focusing on recycling and the use of bio-based plastics to meet the growing consumer demand for environmentally friendly products. This introduction examines the fundamental aspects of plastic molding, its benefits, and the market dynamics that are shaping its future in the contemporary manufacturing ecosystem.

Types of Plastic Molding Processes: An In-Depth Look

Plastic molding is a vital manufacturing process that involves shaping plastic materials into desired forms. There are several types of plastic molding processes, each catering to specific needs and applications.

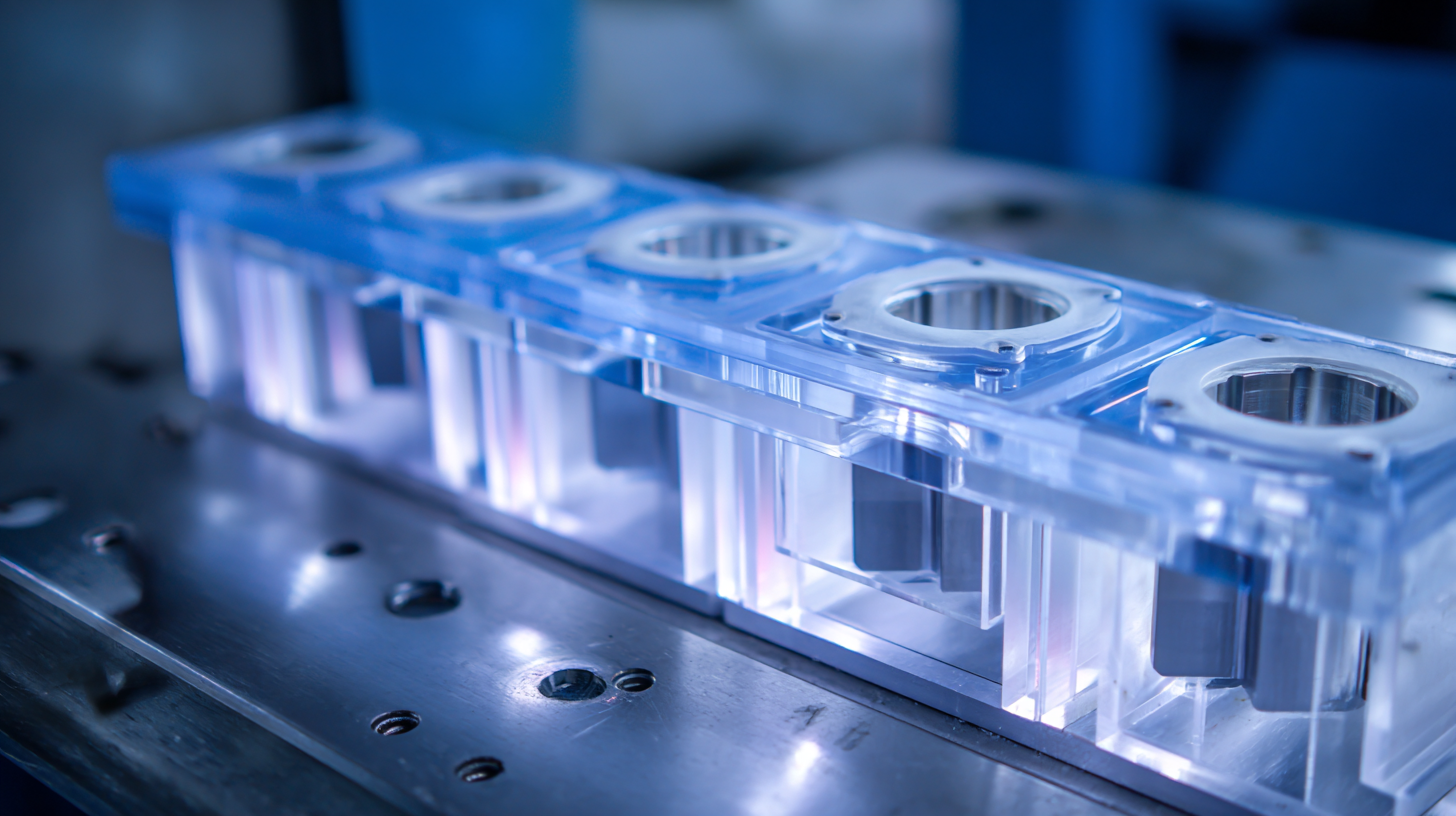

Injection molding, one of the most prevalent methods, utilizes a heated barrel to melt plastic pellets, which are then injected into a mold. This technique is renowned for its ability to produce high volumes of consistent parts with intricate designs, making it ideal for items ranging from automotive components to consumer goods.

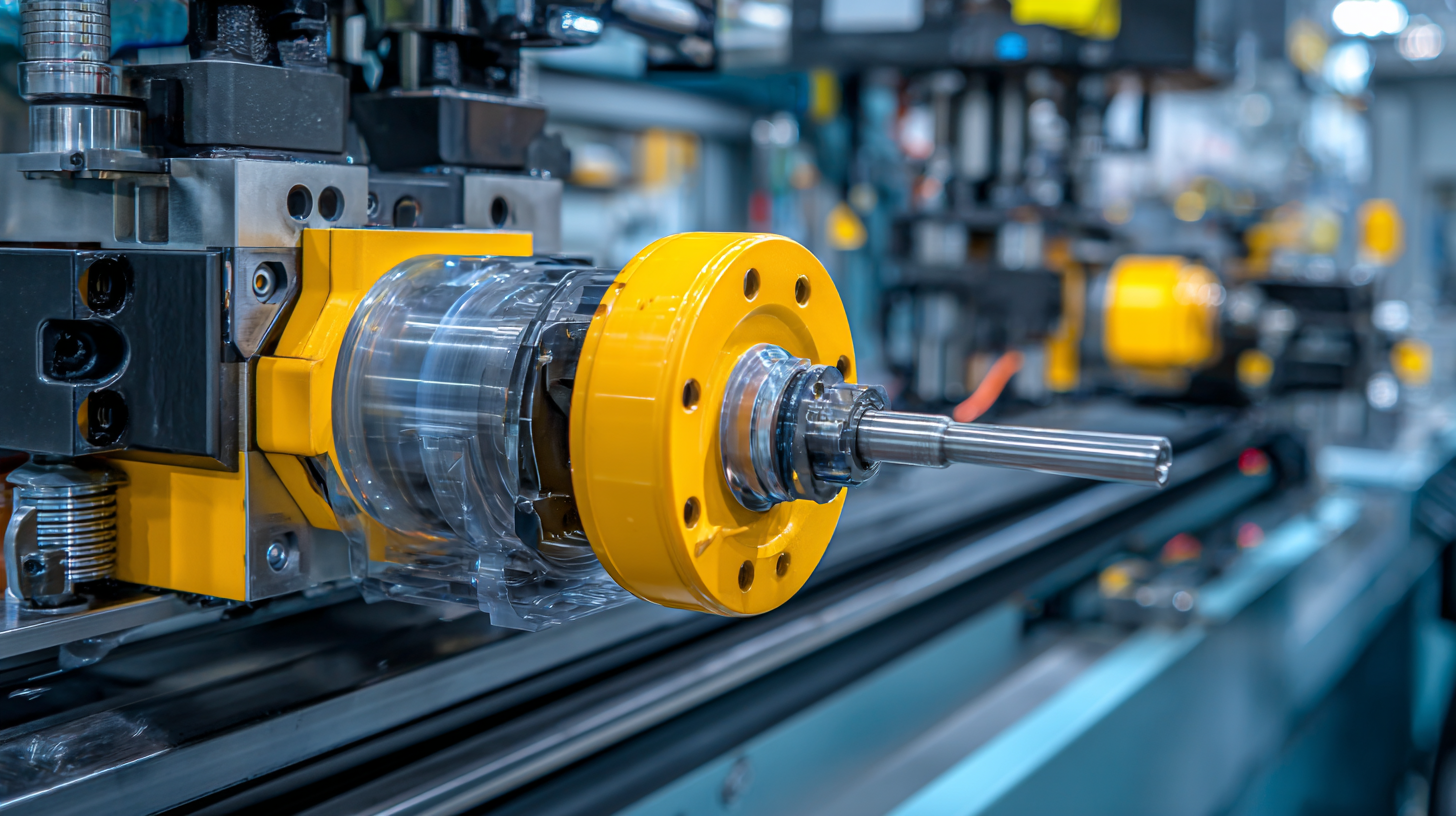

Another notable process is blow molding, primarily used for creating hollow plastic objects such as bottles. In this technique, a heated plastic tube is inflated within a mold to achieve the desired shape, allowing for flexibility in the design of lightweight packaging. Additionally, rotational molding is a lesser-known method that involves the rotation of a mold filled with plastic powder, resulting in thick-walled, hollow products. Each of these molding processes presents unique advantages, ranging from cost-effectiveness to design flexibility, that continue to drive innovation in the plastics industry.

Injection Molding: Efficiency and Versatility in Production

Injection molding stands as a cornerstone of modern manufacturing, offering remarkable efficiency and versatility in production. This process involves injecting molten plastic into a mold, where it cools and solidifies into the desired shape. Ideal for high-volume production runs, injection molding can yield thousands of identical parts rapidly. Its precision in manufacturing not only ensures uniformity but also minimizes waste, making it an environmentally friendly option compared to other methods.

**Tips:** When considering injection molding, it's crucial to select the right type of plastic for your product's intended use. Factors such as temperature resistance, durability, and flexibility should guide your choice, impacting the overall quality and functionality of the finished item. Additionally, collaborating with an experienced mold designer can greatly enhance efficiency and reduce production costs, ensuring your project progresses smoothly from concept to completion.

The versatility of injection molding extends to a wide array of industries, from automotive to consumer goods. Customizable molds can accommodate intricacies and specific requirements, allowing brands to innovate continually. As market trends evolve, embracing advancements in technology, such as automation and smarter materials, can provide a competitive edge and meet the ever-growing demand for sustainability in production processes.

What is Plastic Molding? Exploring Process Types, Benefits, and Market Trends in 2023

| Process Type | Description | Benefits | Market Trends (2023) |

|---|---|---|---|

| Injection Molding | A process of creating parts by injecting molten material into a mold. | High efficiency, minimal waste, and ability to produce complex shapes. | Increasing demand in automotive and consumer goods industries. |

| Blow Molding | A manufacturing process for forming hollow plastic parts. | Low production costs and suitability for large volume production. | Growth in packaging applications and sustainable materials usage. |

| Rotational Molding | A process where powdered plastic is heated and rotated to form hollow objects. | Versatility and ability to create large, durable items. | Rising popularity in outdoor furniture and storage solutions. |

| Thermoforming | Heating plastic sheets and shaping them over a mold. | Cost-effective for low volume and custom parts production. | Expanding in the food packaging market. |

Blow Molding: Creating Hollow Plastic Objects

Blow molding is an innovative manufacturing process that specializes in the creation of hollow plastic objects, widely utilized across various industries, from packaging to automotive parts. This technique involves inflating hot plastic within a mold to achieve the desired shape. According to the MarketsandMarkets report, the blow molding market is expected to grow from $47.6 billion in 2020 to $64.9 billion by 2025, highlighting its increasing significance in plastic production.

Blow molding is an innovative manufacturing process that specializes in the creation of hollow plastic objects, widely utilized across various industries, from packaging to automotive parts. This technique involves inflating hot plastic within a mold to achieve the desired shape. According to the MarketsandMarkets report, the blow molding market is expected to grow from $47.6 billion in 2020 to $64.9 billion by 2025, highlighting its increasing significance in plastic production.

One of the primary benefits of blow molding is its efficiency in producing lightweight, durable products with a consistent wall thickness. The global demand for lightweight packaging, particularly for bottled beverages and consumer goods, mirrors this trend. Furthermore, advancements in blow molding technology, such as the introduction of coextrusion and stretch blow molding, enhance product performance and open new markets. Industry analysts project that as sustainability and recycling practices become more prevalent, the development of eco-friendly materials in blow molding will play a crucial role in shaping the future of the industry.

Rotational Molding: Innovative Techniques for Unique Designs

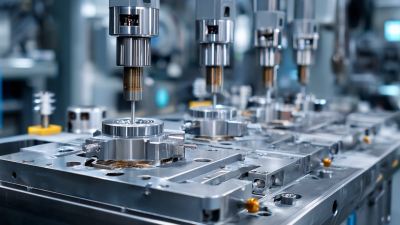

Rotational molding is an innovative manufacturing process that allows for the production of large, hollow plastic parts with complex shapes and designs. Unlike traditional molding techniques such as injection molding, which relies on high pressure and rapid cooling, rotational molding employs a relatively low-pressure process where plastic pellets are heated in a mold and then rotated along two axes. This rotation ensures an even distribution of the material, allowing for the creation of seamless and intricately designed products. According to a 2023 market report from Research and Markets, the global rotational molding market is expected to reach $7.5 billion by 2027, driven by the increasing demand for customized and lightweight components across multiple industries.

One of the significant advantages of rotational molding is its capability to produce large parts with high design flexibility. The process enables manufacturers to incorporate various materials and colors, as well as additional features such as inserts and textures, without escalating production costs. Furthermore, as sustainability becomes a key priority in the plastics industry, rotational molding allows for the use of recycled materials, contributing to circular economy initiatives. A survey conducted by Grand View Research highlights that nearly 45% of companies are integrating eco-friendly practices within their production lines, emphasizing the growing trend towards sustainability in the manufacturing landscape. This shift not only enhances brand reputation but also meets consumer demand for environmentally responsible products.

Market Trends in Plastic Molding: What to Expect in 2023

The plastic molding industry is witnessing notable trends in 2023, driven by advancements in technology and changing consumer demands. One of the key trends is the increasing adoption of sustainable materials. As environmental awareness rises, manufacturers are focusing on biodegradable and recyclable plastics, transitioning away from traditional petroleum-based products. This shift not only addresses ecological concerns but also opens new markets for innovative materials that appeal to eco-conscious consumers.

Another significant trend is the integration of automation and smart manufacturing processes. The use of robotics and artificial intelligence in plastic molding is enhancing efficiency, reducing labor costs, and improving quality control. Companies are investing in advanced machinery that can operate with minimal human intervention, which allows for higher production rates and the ability to meet the growing demand for customized products. Additionally, as the industry increasingly embraces Industry 4.0 principles, real-time data analytics is becoming vital for optimizing production and minimizing waste, further driving competitiveness in the market.

Market Trends in Plastic Molding: Key Processes and Growth Metrics for 2023

Related Posts

-

How to Optimize Your Plastic Injection Molding Process for Maximum Efficiency

-

Revolutionizing Product Development: The Benefits of Rapid Prototype Injection Molding Explained

-

Innovative Uses of Plastic Injection Molding in Sustainable Product Design

-

Injection Mold Maker Comparison Analyzing Cost Efficiency and Quality in Different Manufacturing Techniques

-

What is an Injection Machine and How Does it Transform Manufacturing

-

How to Optimize Your Supply Chain for Plastic Manufacturing Success