10 Reasons Rapid Injection Molding is the Best Choice for Your Production Needs

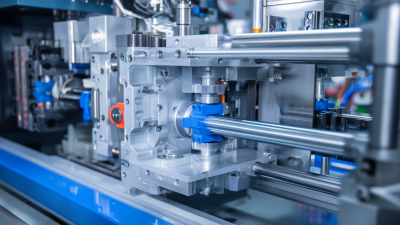

In today’s fast-paced manufacturing environment, businesses are increasingly turning to rapid injection molding as a strategic solution to meet their production needs. According to a report by Grand View Research, the global injection molding market is expected to reach $335.6 billion by 2027, driven by the demand for custom plastic parts and quick turnaround times. Rapid injection molding, which significantly shortens production lead times while maintaining high precision, has emerged as a game-changer for industries ranging from automotive to consumer products. With the ability to produce high-quality prototypes and end-use parts in record time, companies can accelerate their product development cycles, reduce time to market, and enhance overall competitiveness.

As we explore the top ten reasons why rapid injection molding might be the best choice for your production requirements, it's essential to understand how this innovative approach is redefining manufacturing efficiency and responsiveness in an ever-evolving marketplace.

Reasons Why Rapid Injection Molding Streamlines Your Manufacturing Process

Rapid injection molding is revolutionizing the manufacturing industry by offering unparalleled efficiency and speed. One of the primary reasons it streamlines your manufacturing process is through reduced lead times. Traditional injection molding can take weeks, if not months, due to the lengthy design and prototyping phases. In contrast, rapid injection molding uses advanced technologies and materials to significantly shorten these stages, enabling companies to move from concept to production in a matter of days.

Additionally, rapid injection molding supports a more flexible production environment. As manufacturers face the need for quick adaptations to market demands, the ability to easily modify molds and designs becomes crucial. This flexibility not only allows for faster iteration of products but also reduces waste and lowers costs associated with retooling. By integrating rapid injection molding into their processes, businesses can respond swiftly to changes, ensuring that they remain competitive in a fast-paced market.

High Precision and Consistency in Complex Part Production

Rapid injection molding has emerged as a game-changer for manufacturers seeking high precision and consistency in producing complex parts. This innovative process allows for quick turnaround times while maintaining tight tolerances, which is essential in industries like aerospace, automotive, and medical devices. With advanced techniques and materials, manufacturers can achieve intricate designs that meet exact specifications, ensuring that each part produced is identical and reliable.

Moreover, the high precision available through rapid injection molding significantly reduces the risk of defects, which is critical for complex components that require flawless operation. By utilizing computer-aided design (CAD) software and sophisticated machinery, manufacturers can simulate the molding process in advance, ensuring effective quality control before part production begins. This not only streamlines the production process but also enhances overall efficiency, allowing companies to focus on innovation and scaling their operations without sacrificing quality. As a result, rapid injection molding stands out as the optimal solution for meeting the demands of contemporary manufacturing challenges.

10 Reasons Rapid Injection Molding is the Best Choice for Your Production Needs

| Feature | Description | Benefits |

|---|---|---|

| High Precision | Rapid injection molding provides high accuracy in part dimensions. | Ensures parts fit correctly and reduces need for rework. |

| Fast Production | Shorter cycle times compared to traditional methods. | Increases output and speeds up time to market. |

| Consistency | Maintains uniformity across produced parts. | Reduces variability and enhances product quality. |

| Complex Designs | Ability to produce intricate and complex geometries. | Supports innovative designs that attract customers. |

| Material Variety | Compatible with a wide range of polymers and materials. | Offers flexibility to meet diverse project requirements. |

| Cost-Effectiveness | Lower costs associated with shorter production times. | Increases return on investment for production runs. |

| Rapid Prototyping | Facilitates quick verification and testing of designs. | Accelerates the design iteration process. |

| Environmental Impact | Often uses recyclable materials and process efficiency. | Minimizes waste and supports sustainable manufacturing. |

| Scalability | Flexible methods support both small and large batches. | Adaptable production levels as demand changes. |

| Enhanced Collaboration | Encourages closer cooperation between design and production teams. | Improves communication, resulting in better final products. |

Cost-Effectiveness of Rapid Injection Molding Compared to Traditional Methods

The demand for specialized metal powders in additive manufacturing is surging, emerging as a significant market trend. According to recent industry reports, the North American metal powder market is projected to expand at a compound annual growth rate (CAGR) of approximately 6.8% from 2021 to 2028. This growth is primarily fueled by the increasing adoption of additive manufacturing technologies across various sectors, including aerospace and automotive. These industries require high-performance materials that can meet rigorous standards, and specialized metal powders are finding their place as essential components in this innovative landscape.

The cost-effectiveness of rapid injection molding in comparison to traditional methods is also transforming production processes. Rapid injection molding significantly reduces both lead times and production costs, making it an attractive option for manufacturers looking to streamline operations. While conventional methods may involve extensive tooling and longer setup times, rapid injection molding leverages advanced techniques that allow for quick iterations of designs and reduced material waste. This shift not only benefits manufacturers financially but also aligns with the growing trend toward sustainability, further driving the demand for rapid injection molding solutions in the competitive market.

Faster Time-to-Market with Rapid Prototyping and Production

In today’s competitive landscape, bringing products to market quickly is crucial for success. Rapid injection molding offers a streamlined process that significantly reduces both prototyping and production times. By utilizing advanced technologies and methodologies, manufacturers can produce high-quality prototypes in just days, allowing for faster feedback and revisions. This accelerated approach not only shortens the development cycle but also enables businesses to stay ahead of market trends and customer demands.

Moreover, rapid injection molding minimizes costs associated with traditional manufacturing methods. Companies can test and refine their designs without heavy investments in tooling and setup, making it an economical choice for small to medium production runs. As a result, organizations can launch their products sooner and respond to market changes effectively. This agility is not only advantageous in enhancing customer satisfaction but also crucial for maintaining a competitive edge in a fast-paced industry.

10 Reasons Rapid Injection Molding is the Best Choice for Your Production Needs

Flexibility in Material Choices for Diverse Product Applications

Rapid injection molding has emerged as a game-changer in the manufacturing sector, particularly due to its flexibility in material choices, catering to a wide array of product applications. Industry reports indicate that the global injection molding market is projected to reach USD 354.1 billion by 2027, growing at a CAGR of 3.8% from 2020. This growth is driven by the increasing demand for customized and durable products across various industries, including automotive, consumer goods, and medical devices. The ability to select from a diverse range of materials, such as thermoplastics, elastomers, and composites, allows manufacturers to tailor their products to specific performance requirements and environmental considerations.

Rapid injection molding has emerged as a game-changer in the manufacturing sector, particularly due to its flexibility in material choices, catering to a wide array of product applications. Industry reports indicate that the global injection molding market is projected to reach USD 354.1 billion by 2027, growing at a CAGR of 3.8% from 2020. This growth is driven by the increasing demand for customized and durable products across various industries, including automotive, consumer goods, and medical devices. The ability to select from a diverse range of materials, such as thermoplastics, elastomers, and composites, allows manufacturers to tailor their products to specific performance requirements and environmental considerations.

Moreover, with advancements in material technology, many manufacturers can now utilize high-performance materials that were previously challenging to mold. According to a study by Grand View Research, engineering plastics are gaining traction in injection molding applications, attributed to their superior strength and lightweight properties. Materials such as polycarbonate and nylon offer excellent durability and design flexibility, enabling the creation of innovative product designs while minimizing production costs. This flexibility not only enhances product quality but also accelerates time-to-market, reinforcing rapid injection molding as an optimal choice for companies looking to meet ever-evolving consumer demands and industry standards.

Related Posts

-

Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques

-

Global Success of Medical Injection Molding from China Driven by Quality Enhancement

-

Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding