Revolutionizing Product Development: The Benefits of Rapid Prototype Injection Molding Explained

In today's fast-paced market, the ability to innovate and deliver products efficiently is crucial for maintaining a competitive edge. One of the most transformative approaches in product development is rapid prototype injection molding, a technique that significantly accelerates the prototyping process while reducing costs. This method allows manufacturers to create high-quality prototypes in a fraction of the time traditionally required, enabling faster design iterations and more effective testing of concepts. With its ability to produce detailed and functional parts quickly, rapid prototype injection molding not only shortens the development cycle but also enhances collaboration between design teams and stakeholders. As businesses strive for agility and responsiveness, embracing this advanced molding technique becomes essential for those looking to revolutionize their product development processes. In this article, we will explore the numerous benefits of rapid prototype injection molding, offering tips on how to leverage this innovative method to optimize your product development strategy.

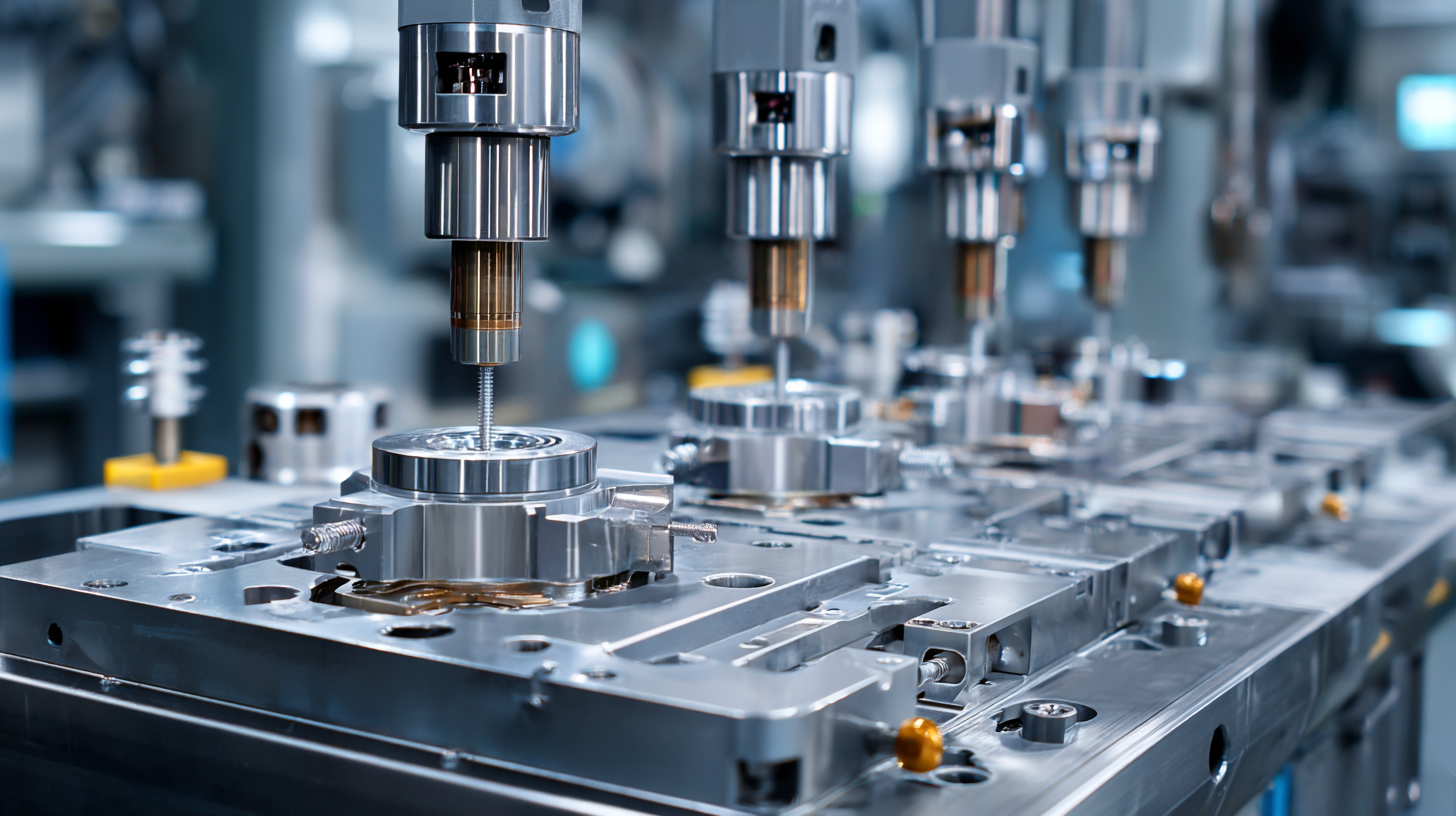

Understanding Rapid Prototype Injection Molding: An Overview

Rapid prototype injection molding is an innovative manufacturing process that drastically enhances product development timelines. This technique enables designers to produce small batches of prototypes quickly, facilitating rapid testing and iteration. According to a report by the Consumer Technology Association, companies utilizing rapid prototyping can reduce their time-to-market by up to 50%. This acceleration is essential in today's fast-paced market, where being first can be a significant competitive advantage.

In addition to speed, rapid prototype injection molding offers flexibility in design. Engineers can make adjustments in real-time based on testing feedback, ensuring that products meet user expectations before full-scale production. A study by the American Society for Quality highlights that incorporating prototyping in the design stage can reduce product failure rates by as much as 30%. This not only improves consumer satisfaction but also optimizes manufacturing processes, resulting in lower overall costs and enhanced efficiency. As industries continue to evolve, the adoption of rapid prototype injection molding will be crucial for businesses aiming to innovate and respond to market demands swiftly.

Benefits of Rapid Prototype Injection Molding

This chart illustrates the various benefits attributed to rapid prototype injection molding, showing the percentage of each benefit in relation to the total. Cost efficiency stands out as the most significant advantage, followed by faster time to market and improved design accuracy.

Key Advantages of Rapid Prototyping in Product Development

Rapid prototyping has emerged as a pivotal methodology in product development, significantly enhancing efficiency and innovation. By utilizing rapid prototype injection molding, companies can swiftly turn concepts into tangible products, reducing the typical development time from months to just weeks. According to a recent industry report by Wohlers Associates, the additive manufacturing market is projected to grow to $35.6 billion by 2024, emphasizing the increasing reliance on rapid prototyping in various sectors. This approach enables businesses to iterate designs quickly, test functionality, and make necessary adjustments before committing to large-scale production.

One of the key advantages of rapid prototyping is cost-effectiveness. Traditional methods often require hefty investments in tooling and materials, which can escalate project costs. However, with rapid injection molding, companies can produce prototypes at a fraction of the cost, enabling them to allocate resources more strategically. A study by Gartner indicates that organizations implementing rapid prototyping see a reduction in product development costs by up to 30%.

Tips: When embarking on your rapid prototyping journey, ensure to select materials that closely resemble your final product. This allows for more accurate testing and feedback. Additionally, consider collaborating with experienced manufacturers to streamline the process and reduce potential delays. By leveraging rapid prototyping, you not only expedite your product development cycle but also enhance the overall quality of your final product.

Streamlining the Design Process with Rapid Prototyping Techniques

Rapid prototyping techniques have transformed the design process in product development, offering manufacturers an efficient avenue to visualize and test concepts before full-scale production. By utilizing methods such as rapid prototype injection molding, designers can quickly create functional prototypes that closely mimic the final product. This allows for iterative testing and refinement, providing invaluable feedback that helps identify potential issues early in the design phase, ultimately saving time and resources.

Moreover, rapid prototyping facilitates enhanced collaboration among design teams, stakeholders, and clients. With tangible prototypes in hand, discussions become more focused and productive, as all parties can interact with a physical representation of the concept. This immediate feedback loop accelerates decision-making and fosters innovation, as designers can swiftly pivot based on input received during the prototyping stage. As a result, rapid prototyping not only streamlines the design process but also enables organizations to bring cutting-edge products to market faster, enhancing their competitive edge in an increasingly fast-paced industry.

Cost-Effectiveness of Rapid Prototype Injection Molding

Rapid prototype injection molding is increasingly recognized for its cost-effectiveness in product development. According to a report by the Association for Manufacturing Technology, companies utilizing rapid prototype techniques can reduce overall production costs by up to 30%, mainly due to decreased lead times and minimized material waste. This method allows manufacturers to create multiple design iterations quickly, enabling faster decision-making and lowering the expenses associated with traditional prototyping methods.

Moreover, the flexibility of rapid prototype injection molding significantly contributes to its economic advantages. A study by the American Society of Mechanical Engineers indicates that prototyping costs can drop as much as 50% when using rapid injection methods over conventional tooling. This reduction stems from the ability to use cheaper materials for initial prototypes and fewer resources needed to modify designs swiftly. As companies strive for shorter time-to-market periods, adopting rapid prototype injection molding not only accelerates the development process but also enhances budget management, making it a strategic investment in modern manufacturing.

Case Studies: Successful Applications of Rapid Prototyping in Industry

Rapid prototyping has become a game-changer in various industries, showcasing its effectiveness through numerous successful applications. For instance, in the automotive sector, companies like Ford have leveraged rapid prototype injection molding to accelerate their product development cycles. By quickly producing small batches of prototype parts, Ford can test designs, gather feedback, and make necessary adjustments in real-time, significantly shortening the time from concept to market.

In the consumer electronics field, a prominent case is that of Apple. By embracing rapid prototyping, Apple has managed to streamline the development of its devices, allowing for expedited iterations on design and functionality. This approach not only enhances innovation but also enables Apple to stay ahead in a competitive market by rapidly addressing consumer feedback and technological advancements. Such case studies highlight the substantial impact of rapid prototyping in driving efficiency and creativity across various industries.

Related Posts

-

Ultimate Guide to Choosing the Right Injection Machine for Your Manufacturing Needs

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

What is an Injection Machine and How Does it Transform Manufacturing

-

Unlocking the Future of Product Development with Rapid Injection Molding Techniques

-

5 Essential Tips for Sourcing Small Run Plastic Injection Molding: A Global Buyer’s Guide

-

Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques