Top 10 Medical Injection Molding Companies and Their Technology Innovations

The medical industry continually evolves, with innovation serving as the backbone of its advancements. Among the key technologies driving this progress is medical injection molding, a process crucial for producing complex and precise components used in various medical devices and equipment. As the demand for high-quality medical products rises, fostering excellence in manufacturing processes becomes imperative for companies in this sector.

This article delves into the top 10 medical injection molding companies, highlighting their commitment to technological innovations that meet the rigorous standards of the healthcare industry. From biocompatible materials to advanced molding techniques, these companies are at the forefront of transforming medical device manufacturing. By examining their pioneering technologies and strategies, we gain insight into the future of medical injection molding and its vital role in ensuring patient safety and effective treatment outcomes.

Overview of Medical Injection Molding in the Healthcare Sector

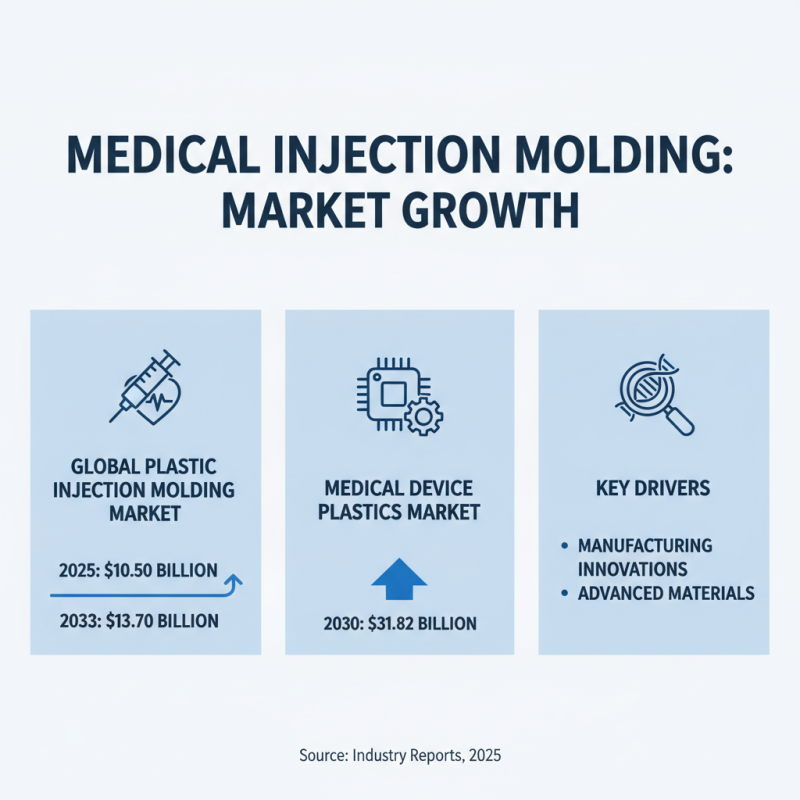

The medical injection molding sector plays a critical role in the healthcare industry, enabling the production of complex medical devices and consumables. As of 2025, the global plastic injection molding market is valued at approximately USD 10.50 billion and is projected to grow to around USD 13.70 billion by 2033. This growth underscores the increasing demand for high-quality, precise medical components made from advanced polymers. Particularly, the medical device plastics market is expected to reach an impressive USD 31.82 billion by 2030, driven by innovations in manufacturing processes and material development.

Technological advancements are also shaping the future of medical injection molding. Notably, the acquisition of injection and rotary platen technologies signifies a shift towards enhanced efficiency and precision in manufacturing processes. Furthermore, the rising trend of micro injection molding showcases the industry's movement towards producing ultra-small components with intricate designs. This technique is expected to see its market size rise from USD 551.3 million in 2025 to USD 759.2 million by 2032, indicating a robust CAGR of 4.7%. These developments reflect the ongoing commitment to innovation in the healthcare sector, ensuring that medical products meet the evolving needs of patients and healthcare providers alike.

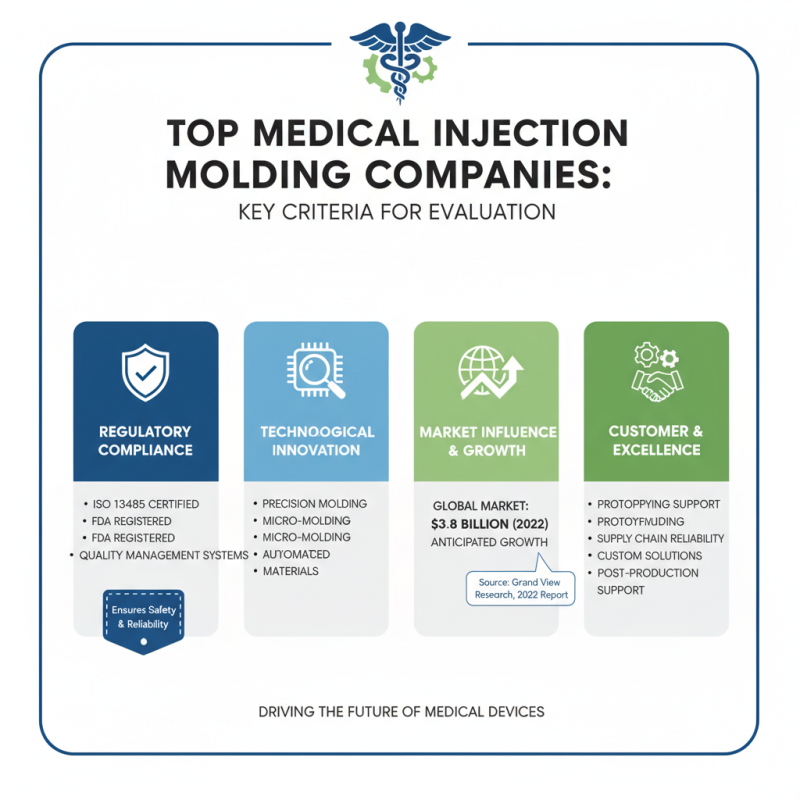

Criteria for Evaluating Top Medical Injection Molding Companies

When evaluating the top medical injection molding companies, several criteria emerge as essential for assessing their capabilities and innovations. First, the company's adherence to regulatory standards, such as ISO 13485 and FDA compliance, is crucial. These certifications not only ensure quality management systems but also demonstrate a commitment to producing reliable and safe medical devices. According to a 2022 report by Grand View Research, the global medical injection molding market was valued at approximately $3.8 billion and is anticipated to grow significantly, underscoring the importance of regulatory adherence in sustaining market competitiveness.

Another key criterion is the level of technological innovation that a company brings to the landscape. Companies leveraging advanced technologies, such as automation and robotics, can enhance precision and efficiency in the molding process. A study by Mordor Intelligence indicates that the incorporation of Industry 4.0 technologies in manufacturing could increase production efficiency by up to 30% in the coming years. Additionally, the ability to incorporate bio-compatible materials and design complex geometries using 3D modeling demonstrates a company's capacity to meet the evolving needs of the healthcare industry, making innovation a critical factor in evaluating top players in this sector.

Innovations in Material Science for Medical Injection Molding

Innovations in material science are crucial for the advancement of medical injection molding, which plays a significant role in enhancing device functionality and patient outcomes. As the demand for minimally invasive surgeries grows, the need for simplified device designs and improved efficiency is emerging as a driving force behind material innovations. The global market for medical injection molded plastics is projected to expand from $27.68 billion in 2025 to $38.18 billion by 2033, reflecting a robust growth trajectory that underscores the pivotal role of advanced materials in the healthcare sector.

Tips: When exploring material innovations, consider how biocompatibility, durability, and sustainability can influence product design. Investing in biodegradable materials can not only enhance the environmental footprint of medical devices but also meet the evolving expectations of consumers who increasingly favor sustainable options.

Ongoing advancements in microextrusion and surface modification techniques are enabling the development of ultra-thin, high-strength components that cater to the specialized needs of modern medical devices. As industry players continue to innovate, the integration of these advanced materials into injection molding processes will yield next-generation medical devices that are both efficient and effective in delivering healthcare solutions.

Leading Technologies in Medical Injection Molding Processes

The medical injection molding industry is experiencing significant technological advancements. As the global micro injection molding machine market is projected to grow substantially, reaching approximately $759.2 million by 2032, innovations in this sector are crucial. Companies are focusing on enhancing precision, reducing errors, and improving overall efficiency through advanced machinery. For instance, developing machines that address common issues such as cross-connection errors and inconsistent setups is critical for maintaining high levels of quality in medical devices.

Additionally, the medical injection molded plastics market is on an upward trajectory, anticipated to grow from $27.68 billion in 2025 to $38.18 billion by 2033. This growth highlights the increasing demand for reliable and efficient manufacturing processes in the medical field. The integration of smart technologies and automation in injection molding processes is not only streamlining production but also addressing challenges like staffing shortages and operational inefficiencies. As the industry evolves, continuous innovation remains at the forefront of improving the medical injection molding landscape.

Top 10 Medical Injection Molding Companies and Their Technology Innovations - Leading Technologies in Medical Injection Molding Processes

| Company Location | Technology Innovations | Specialties | Sustainability Efforts | Market Applications |

|---|---|---|---|---|

| North America | Advanced thermoplastic materials | Surgical instruments, drug delivery systems | Biodegradable materials usage | Healthcare, diagnostics |

| Europe | Precision molding technologies | Orthopedic devices, custom implants | Recycling initiatives | Surgery, therapeutics |

| Asia | Robotic injection molding | Diagnostic devices, infusion pumps | Energy-efficient manufacturing | Patient monitoring, diagnostics |

| North America | Smart molding technology | Catheters, disposable products | Waste reduction programs | Emergency care, surgical |

| Europe | Micro-molding technology | Microfluidics, testing equipment | Low-carbon initiatives | Laboratory, biotech |

Case Studies of Innovative Products from Top Companies

In the realm of medical injection molding, innovation is key to advancing healthcare solutions. One prominent company, Medtronic, has developed a groundbreaking drug delivery system that utilizes advanced molding techniques to create complex devices with precise dosing mechanisms. Their latest insulin pump is designed for ease of use and reliability, showcasing how injection molding technology can enhance patient care through improved functionality and comfort.

Another notable case study comes from Gerresheimer, which has successfully implemented intelligent design in the production of pre-filled syringes. By integrating smart materials and user-friendly features, their syringes not only streamline the medication administration process but also ensure patient safety. This combination of innovation and practicality underscores the impact that cutting-edge injection molding technologies have on the lifecycle of medical products, from development to end-use.

Top 10 Medical Injection Molding Companies - Technology Innovations

Related Posts

-

Global Success of Medical Injection Molding from China Driven by Quality Enhancement

-

Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

Unlocking the Future of Product Development with Rapid Injection Molding Techniques

-

The Definitive Ultimate Guide to Sourcing the Perfect Injection Machine for Your Business Needs

-

How to Optimize Your Supply Chain for Plastic Manufacturing Success