Top Plastic Part Manufacturing Techniques You Need to Know

The landscape of plastic part manufacturing has seen remarkable evolution in recent years, driven by advancements in technology and increasing demand across various industries. According to a report by Grand View Research, the global plastic parts market is expected to reach approximately $500 billion by 2025, highlighting the critical role plastic components play in sectors such as automotive, aerospace, medical, and consumer goods. As manufacturers strive to meet the high standards for quality and efficiency, understanding the most effective manufacturing techniques becomes essential for staying competitive.

In the realm of plastic part manufacturing, techniques such as injection molding, 3D printing, and blow molding are creating new opportunities for innovation and customization. For instance, a recent study by MarketsandMarkets indicates that the injection molding segment alone is projected to grow at a CAGR of 4.5% from 2021 to 2026, emphasizing its significance in producing complex geometries with precision and speed. This overview aims to delve into the key manufacturing techniques that are reshaping the industry, providing insights into their processes, applications, and advantages for manufacturers committed to excellence in plastic component production.

Overview of Plastic Part Manufacturing Techniques

When it comes to plastic part manufacturing, understanding the various techniques available is essential for optimizing production efficiency and ensuring product quality. One of the most widely used methods is injection molding, which involves injecting molten plastic into a mold to create precise shapes. This technique is favored for its ability to produce complex geometries with high repeatability, making it ideal for mass production. Additionally, its versatility allows for the use of a variety of materials, catering to different mechanical and aesthetic requirements.

Another popular technique is blow molding, which is primarily used for creating hollow plastic parts such as containers and bottles. This process involves inflating a heated plastic tube within a mold, resulting in a lightweight yet durable product. Blow molding is particularly advantageous for industries looking to produce large volumes of consistent, high-quality items. Lastly, 3D printing, also known as additive manufacturing, has emerged as a significant technique in recent years. It allows for rapid prototyping and customization, making it an excellent choice for short production runs and intricate designs that would be challenging to achieve with traditional methods.

Injection Molding: The Most Common Method

Injection molding is widely recognized as the most common method for manufacturing plastic parts, owing to its efficiency and scalability. This process involves creating a mold into which melted plastic is injected under high pressure. Once the plastic cools and solidifies, the mold is opened to release the finished part. This technique allows for high precision and consistency in the production of complex shapes, making it ideal for both small and large production runs.

One of the key advantages of injection molding is its ability to utilize a wide variety of thermoplastic materials, which can be formulated to meet specific requirements, such as strength, flexibility, and resistance to chemicals. Moreover, the speed at which parts can be produced—often in seconds per unit—greatly enhances production efficiency.

As a result, businesses can lower costs and increase their output, making injection molding a preferred choice in various industries, from automotive to consumer goods. Overall, the combination of rapid production times, design flexibility, and cost-effectiveness makes injection molding an indispensable technique in plastic part manufacturing.

Blow Molding: Creating Hollow Plastic Parts

Blow molding is a popular manufacturing process used to create hollow plastic parts, making it an essential technique in the plastics industry. This method begins with melting plastic into a pliable state, forming it into a parison—a hollow tube of plastic. Then, the parison is clamped into a mold. Air is blown into the parison, expanding it to fill the mold's cavity. This results in a seamless hollow part that can be customized in various sizes and shapes, ranging from bottles to automotive components.

One of the key advantages of blow molding is its efficiency in mass production. The speed of the process allows manufacturers to produce large quantities of products with consistent quality. Additionally, blow molding uses minimal material waste, as any excess plastic can often be recycled back into the process. This technique not only offers cost savings but also supports sustainability in manufacturing practices. Versatile and effective, blow molding plays a crucial role in meeting diverse consumer needs across numerous industries.

Blow Molding Technology: Production of Hollow Plastic Parts

3D Printing: Innovative Prototyping in Plastic Production

3D printing has transformed the landscape of plastic part manufacturing, presenting innovative approaches for prototyping that significantly enhance production efficiency. According to a recent report by Grand View Research, the global 3D printing market is expected to reach $44.39 billion by 2026, demonstrating a compound annual growth rate (CAGR) of 23%. This rapid growth underscores the technology's increasing adoption in various industries, particularly in creating prototypes that can expedite the design and testing phases.

The versatility of 3D printing allows manufacturers to produce complex geometries and customized designs that were previously unachievable with traditional methods. A study by Wohlers Associates found that over 70% of respondents from the additive manufacturing industry reported substantial time savings during the prototyping stage due to 3D printing. This efficiency not only reduces lead times but also minimizes material waste, as additive manufacturing processes use only the material needed for the prototype. With advancements in materials and printing technologies, 3D printing continues to pave the way for smarter, more efficient plastic production processes, positioning itself as a crucial technique in the manufacturing toolkit.

Top Plastic Part Manufacturing Techniques You Need to Know - 3D Printing: Innovative Prototyping in Plastic Production

| Technique | Description | Advantages | Common Applications |

|---|---|---|---|

| Fused Deposition Modeling (FDM) | A 3D printing process that uses a continuous filament of thermoplastic material. | Cost-effective, suitable for a variety of materials, and great for functional prototypes. | Prototyping, low-volume production, product testing. |

| Stereolithography (SLA) | A vat polymerization process that uses a laser to cure liquid resin into hardened plastic. | High precision and detail, smooth surface finish, and fast prototyping. | Dental models, jewelry design, engineering prototypes. |

| Selective Laser Sintering (SLS) | A 3D printing technology that uses laser to fuse powdered material into solid structures. | Strong and durable parts, complex geometries, and no support structures needed. | Functional prototypes, low-volume manufacturing, aerospace parts. |

| PolyJet Printing | Uses inkjet technology to jet photopolymer droplets which are cured by UV light. | High resolution, multi-material capabilities, and quick turnaround time. | Concept models, prototypes requiring multiple materials, and custom tooling. |

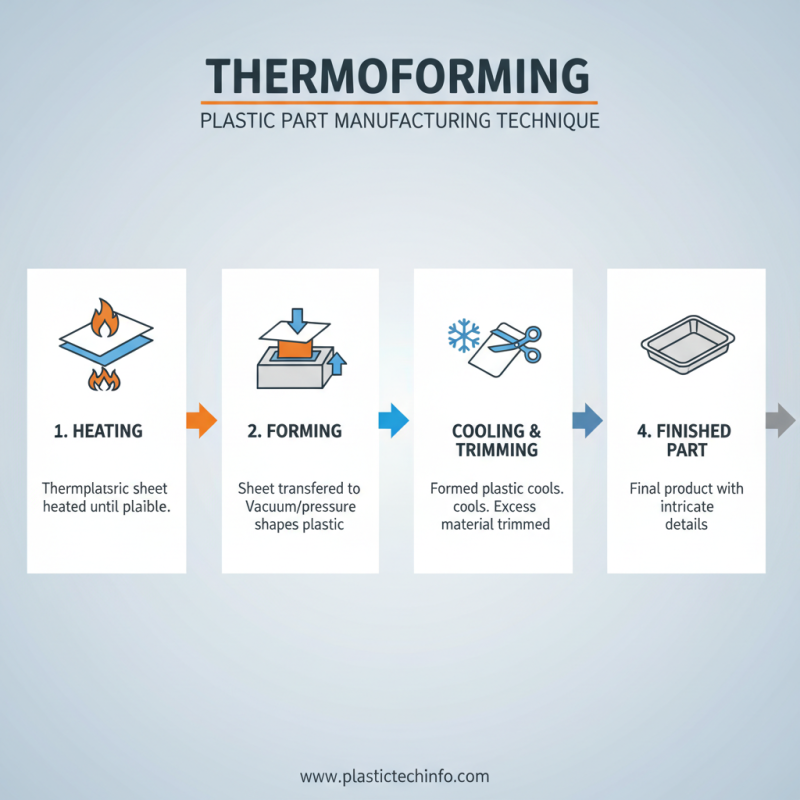

Thermoforming: Shaping Plastic with Heat and Pressure

Thermoforming is a vital plastic part manufacturing technique that utilizes heat and pressure to shape plastic into desired forms. The process begins with a thermoplastic sheet that is heated until it becomes pliable. Once the material reaches the appropriate temperature, it is transferred to a mold where it is formed under a combination of vacuum or pressure. This allows the plastic to conform to the mold's contours, creating intricate details and shapes that are essential for many applications.

One of the key advantages of thermoforming is its versatility. It can be used to create a wide array of products, from simple packaging designs to complex components found in automotive and medical industries. The ability to produce large quantities of parts efficiently, along with the relatively low tooling costs compared to other methods like injection molding, makes thermoforming an attractive choice for manufacturers. Additionally, thermoforming can accommodate various material types, enabling a broad range of finishes and textures, which enhances the aesthetic and functional properties of the final product.

Related Posts

-

The Definitive Ultimate Guide to Sourcing the Perfect Injection Machine for Your Business Needs

-

Revolutionizing Product Development: The Benefits of Rapid Prototype Injection Molding Explained

-

Innovative Uses of Plastic Injection Molding in Sustainable Product Design

-

What is Plastic Molding? Exploring Process Types, Benefits, and Market Trends in 2023

-

Why Plastic Injection Molding is Essential for Modern Manufacturing Success

-

What is an Injection Machine and How Does it Transform Manufacturing