Transform Your Production Line: The Ultimate Guide to Rapid Injection Molding Techniques

In the fast-paced manufacturing landscape, the demand for efficiency and speed has positioned rapid injection molding as a transformative solution across various industries. This innovative technique allows manufacturers to significantly reduce production times while maintaining high levels of precision and quality. According to a report by the Market Research Future, the global rapid injection molding market is projected to grow at a compound annual growth rate (CAGR) of 12.4% from 2020 to 2027, indicating a robust shift towards more agile production processes. Notably, rapid injection molding not only minimizes lead times but also enables the creation of complex geometric shapes, which are increasingly necessary in sectors such as automotive, healthcare, and consumer goods. As businesses adopt these advanced methodologies, understanding and implementing rapid injection molding techniques can be a crucial factor in enhancing competitive edge and operational efficiency.

Innovative Speed: Understanding the Basics of Rapid Injection Molding

Rapid injection molding is redefining manufacturing efficiency, blending speed and innovation to meet the ever-increasing demands of the industry. Recent advancements underscore the importance of understanding the basics of rapid injection molding, where techniques now leverage 3D printing and sophisticated process innovations. For instance, the development of infinitely reusable molds is revolutionizing production by minimizing waste while significantly decreasing costs. This is crucial as the global push for sustainability in manufacturing peaks, aligning with market research indicating a growing preference for eco-friendly practices in various sectors.

Moreover, the introduction of rapid, flexible molding techniques is facilitating quicker design iterations, allowing companies to respond rapidly to market changes. For example, advancements such as closed molding systems have been shown to dramatically decrease injection times, enhancing production rates by over 30%. As industries from automotive to consumer goods increasingly adopt these innovations, understanding the integration of 3D printing into moldmaking processes becomes essential. This knowledge equips manufacturers to harness cutting-edge technologies, ensuring competitive advantage and fostering a culture of continuous improvement in production methodologies.

Transform Your Production Line: The Ultimate Guide to Rapid Injection Molding Techniques

| Technique | Material Type | Cycle Time (seconds) | Output per Hour | Advantages |

|---|---|---|---|---|

| Conventional Injection Molding | ABS | 30 | 120 | High precision, good surface finish |

| Rapid Prototyping | Polycarbonate | 20 | 180 | Fast turnaround for prototypes |

| Gas-Assisted Injection Molding | Nylon | 25 | 140 | Reduced material waste, lighter parts |

| Thin Wall Injection Molding | PP | 15 | 240 | Lower raw material costs, faster cooling |

| Overmolding | TPE | 28 | 130 | Enhanced product functionality, reduced assembly time |

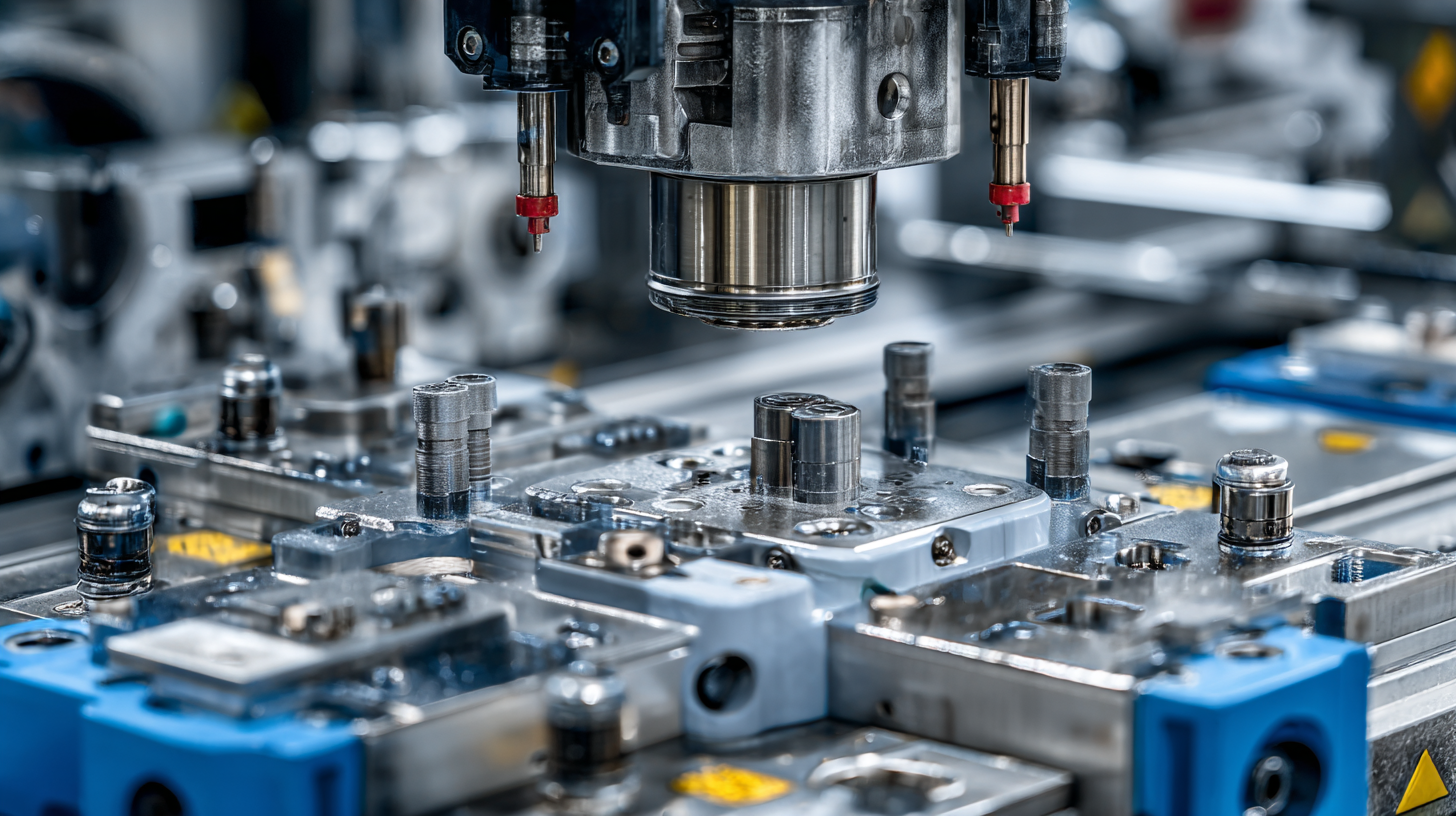

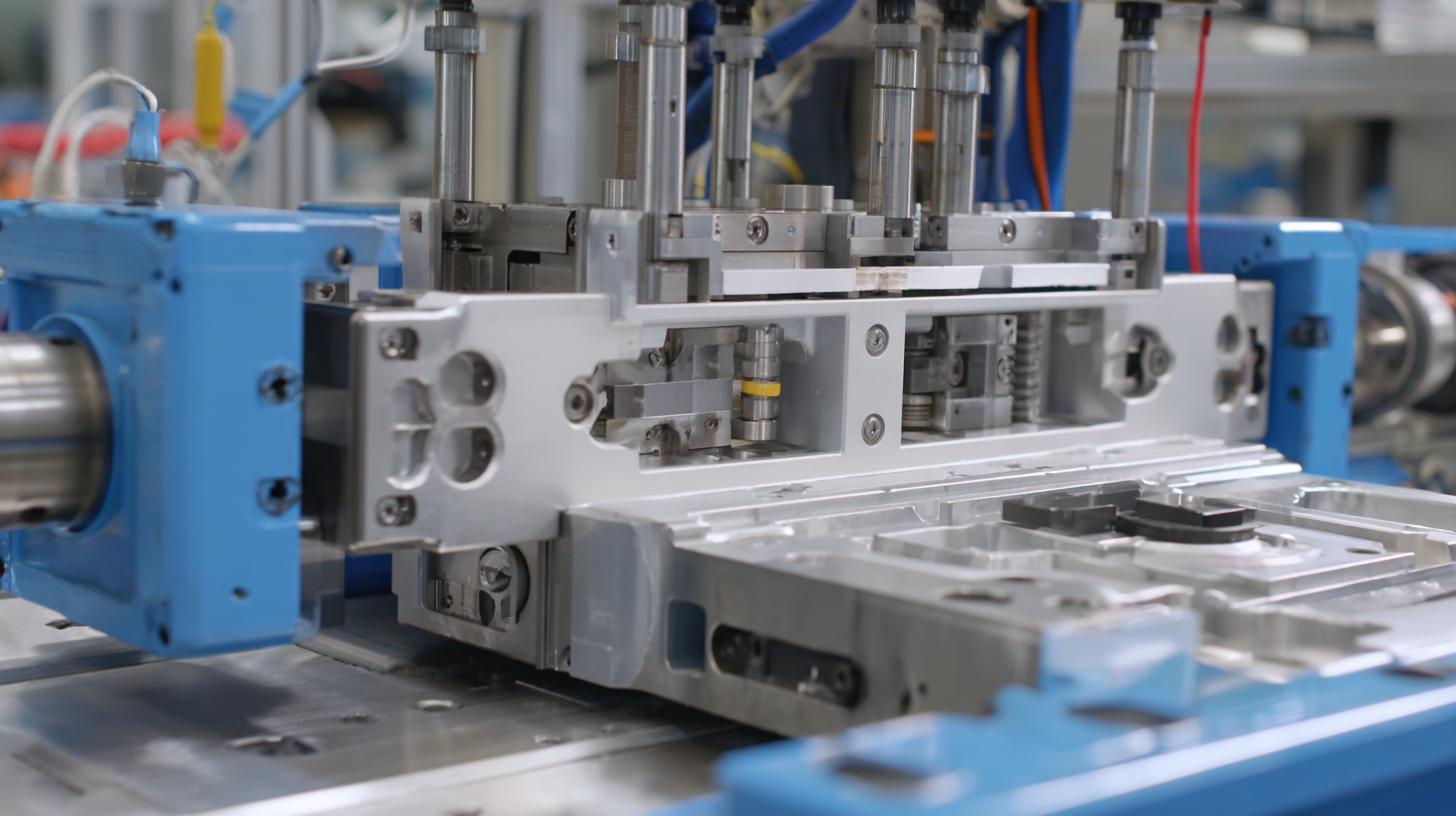

Optimizing Your Production Line: Essential Equipment and Technology

In today’s competitive landscape, optimizing production lines through advanced technologies is crucial for manufacturers aiming to enhance efficiency and reduce costs. Rapid injection molding techniques, which utilize cutting-edge equipment and processes, facilitate quicker turnaround times and greater flexibility in production. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $339.6 billion by 2026, reflecting a compound annual growth rate (CAGR) of 3.2% from 2021 to 2026. This growth highlights the increasing importance of investing in state-of-the-art machinery to remain competitive.

Essential equipment for optimizing production lines includes robotic automation systems, intelligent mold design, and advanced monitoring technologies. Automation not only streamlines workflows but also minimizes human error, which can significantly lower production costs. A study published by Research and Markets indicates that investments in automation can lead to a 30% reduction in labor costs and a 20% increase in production efficiency. By integrating these technologies into their production lines, manufacturers can enhance product quality while meeting the rising demand for customized solutions with shorter lead times.

Material Matters: Choosing the Right Polymers for Speed and Quality

When it comes to optimizing production processes, the choice of polymer materials is crucial, especially in the fast-paced environment of the diaper industry. As the global market for diapers is expected to reach a value of approximately $117.7 billion by 2025, the selection of materials that can improve both speed and quality is more important than ever. The right polymers not only enhance the functionality of the product but also significantly impact production efficiency.

Recent reports suggest that the compound annual growth rate (CAGR) for the diaper market is projected at 7.0%, highlighting the demand for innovative manufacturing techniques such as rapid injection molding. By choosing the appropriate polymers, manufacturers can achieve faster cycle times without compromising product integrity. For instance, materials designed for quick injection and cooling can help reduce lead times and enhance overall productivity, making it essential for manufacturers to stay informed about the latest advancements in polymer technology to maintain a competitive edge.

Material Matters: Choosing the Right Polymers for Speed and Quality

This chart illustrates the influence of different types of polymers on the speed and quality of rapid injection molding processes.

Streamlining Processes: Tips for Reducing Cycle Time in Injection Molding

Reducing cycle time in injection molding is crucial for enhancing productivity and efficiency within your production line. One effective strategy is to optimize the mold design. By simplifying complex geometries and ensuring proper venting, you can achieve faster fill times and minimize the occurrences of defects. Moreover, utilizing advanced materials with better flow properties can allow for quicker cycle completions without sacrificing product quality.

Another key approach is to automate processes wherever possible. Implementing robotic systems for part removal and other repetitive tasks reduces the manual intervention needed and accelerates the overall production cycle. Alongside, regular maintenance of machines ensures they operate at peak efficiency, preventing delays caused by equipment failure. Finally, monitoring cycle times through data analytics can provide insights into bottlenecks, enabling targeted interventions for further streamlining operations. By embracing these strategies, manufacturers can significantly reduce cycle times and improve the overall effectiveness of their injection molding processes.

Quality Control: Ensuring Consistent Results in Rapid Production Environments

In the fast-paced environment of rapid injection molding, quality control is paramount to ensure consistent and reliable results. Implementing stringent quality measures throughout the production process can mitigate defects and enhance product integrity. This begins with selecting high-quality raw materials, as even minor variances in material composition can lead to significant differences in the final products. Regular monitoring of material properties, coupled with thorough inspection protocols, establishes a strong foundation for maintaining consistent quality.

Moreover, the use of advanced monitoring technologies, such as in-line sensors and data analytics, allows manufacturers to identify potential issues in real-time. These technologies facilitate immediate adjustments to the molding parameters, ensuring that the production remains within specified tolerances. Additionally, employee training on quality assurance processes is essential; it fosters a culture of accountability and attention to detail that permeates the production line. By prioritizing these elements of quality control, manufacturers can confidently meet market demands for rapid production without compromising product excellence.

Related Posts

-

10 Reasons Rapid Injection Molding is the Best Choice for Your Production Needs

-

Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques

-

Exploring Cost Efficiency in Low Cost Injection Molding at 2025 China Import and Export Fair

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape

-

5 Essential Tips for Sourcing Small Run Plastic Injection Molding: A Global Buyer’s Guide