Ultimate Guide to Small Run Plastic Injection Molding for Global Buyers

In the realm of manufacturing, small run plastic injection molding has emerged as a vital solution for businesses looking to develop prototypes or smaller quantities of products without incurring the high costs commonly associated with mass production. This comprehensive guide is designed to equip global buyers with essential knowledge and practical tips to navigate the complexities of small run plastic injection molding.

We will explore the advantages of this method, including its cost-effectiveness and flexibility, while also addressing potential challenges buyers might face. Whether you're a startup launching your first product or an established company seeking to test new designs, understanding the nuances of small run plastic injection molding can significantly impact your production strategy and overall success.

Join us as we delve into the world of small-scale manufacturing and empower your purchasing decisions with expert insights.

We will explore the advantages of this method, including its cost-effectiveness and flexibility, while also addressing potential challenges buyers might face. Whether you're a startup launching your first product or an established company seeking to test new designs, understanding the nuances of small run plastic injection molding can significantly impact your production strategy and overall success.

Join us as we delve into the world of small-scale manufacturing and empower your purchasing decisions with expert insights.

Understanding Small Run Plastic Injection Molding: Key Concepts for Buyers

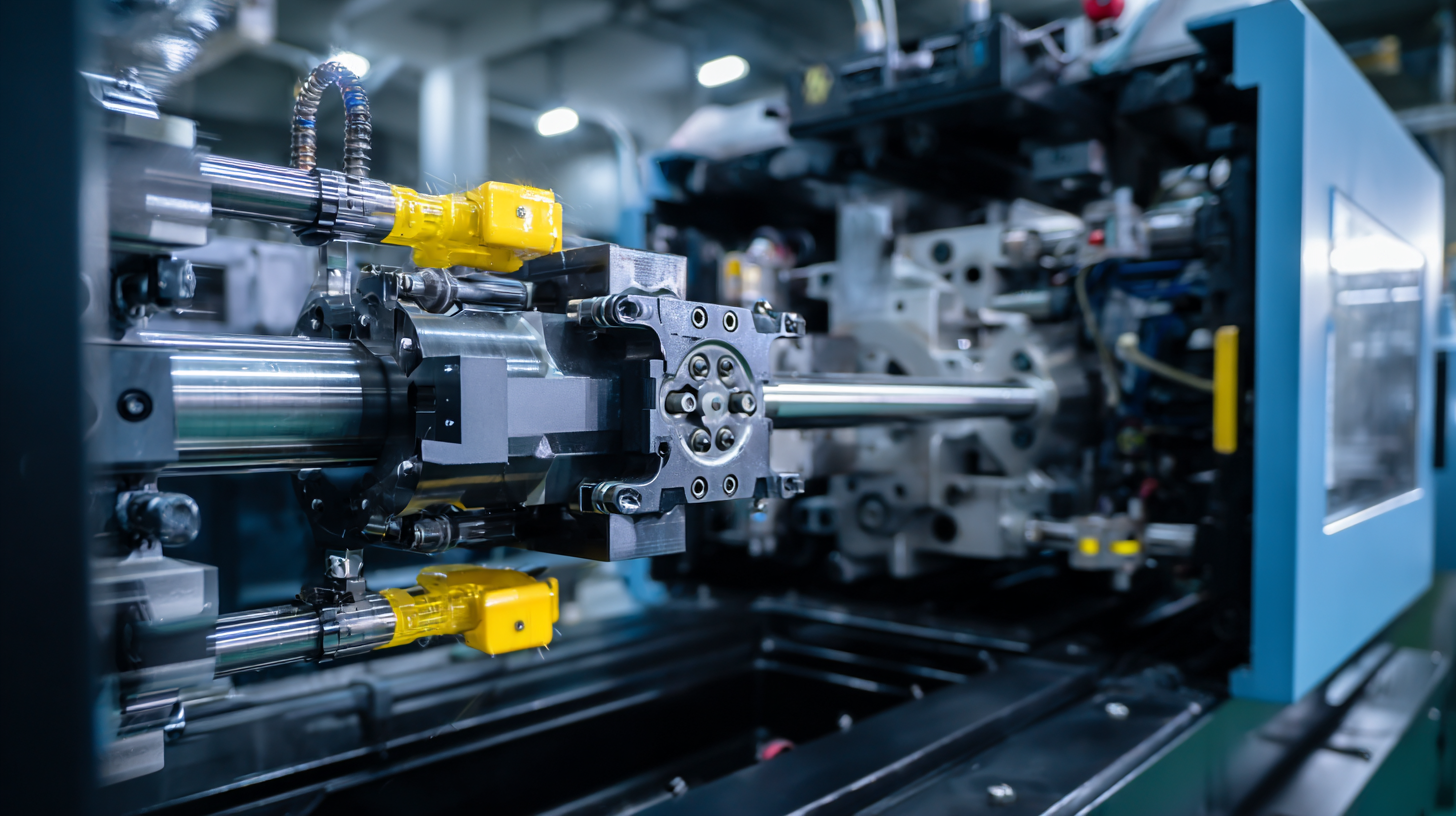

Small run plastic injection molding is an essential process for buyers looking to produce plastic parts in limited quantities without sacrificing quality. Understanding the key concepts surrounding this manufacturing method can significantly impact both cost and efficiency.

Unlike traditional mass production, small run injection molding allows for greater flexibility in design and material selection. This is particularly beneficial for startups or companies looking to test new products or enter niche markets.

One crucial aspect of small run injection molding is the choice of materials. Buyers need to consider the specific requirements of their project, such as strength, durability, and heat resistance.

Additionally, the selectivity in molds can influence both the time-to-market and overall project costs. By collaborating closely with experienced manufacturers, buyers can ensure that they receive expert guidance on material options and design considerations, ultimately leading to a more effective production process tailored for their unique needs.

Choosing the Right Materials for Your Small Run Injection Molding Project

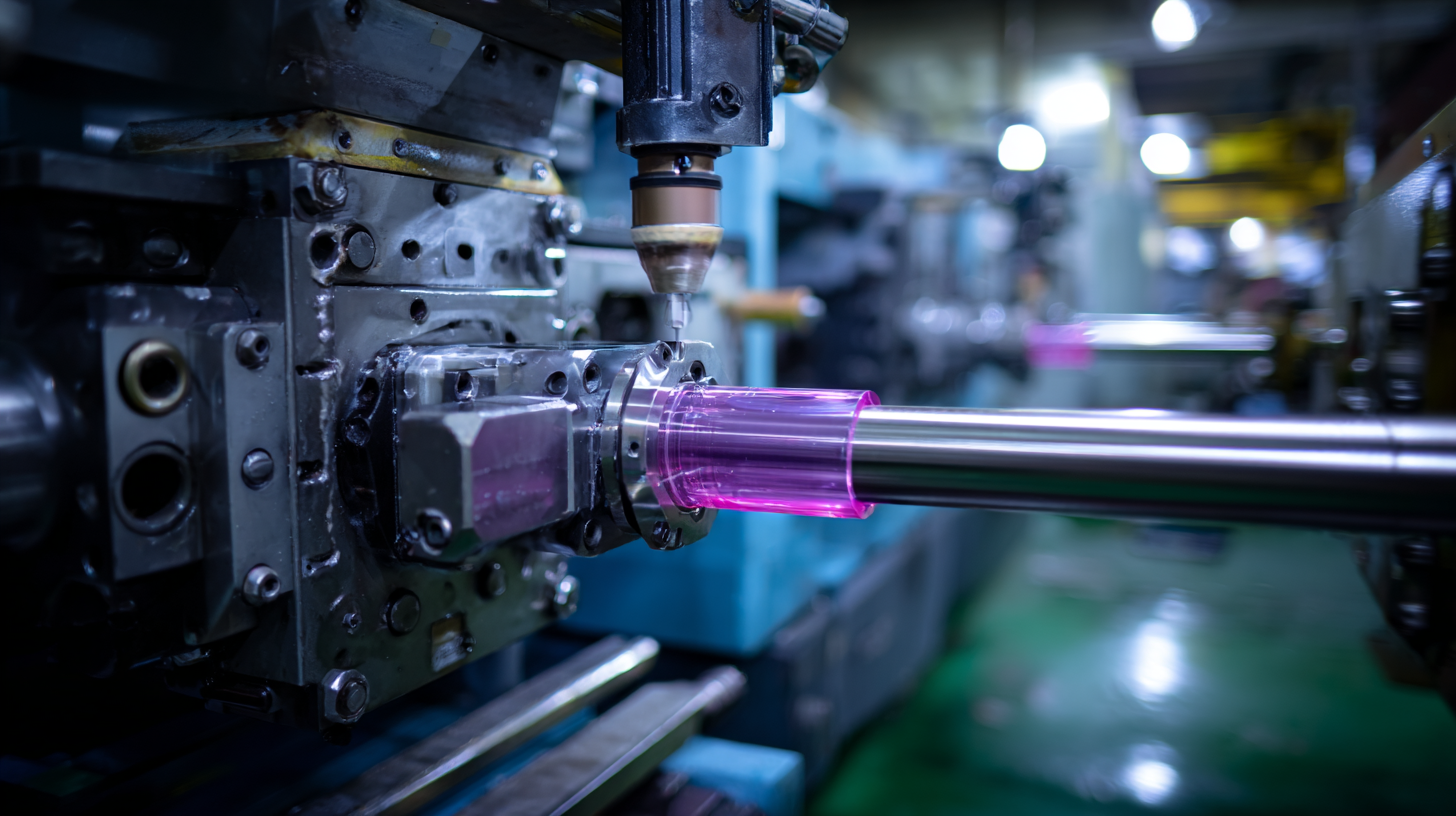

When embarking on a small run injection molding project, selecting the right materials is crucial to the overall success of your product. The material you choose will significantly impact not only the durability and performance of the final product but also the cost-effectiveness of your project. Common materials include thermoplastics like ABS, polycarbonate, and nylon, each offering unique properties suited to different applications. For instance, ABS is known for its strength and impact resistance, making it ideal for consumer goods, while polycarbonate provides excellent clarity and UV resistance, suitable for transparent applications.

It's equally important to consider the environmental impact and sustainability of the materials chosen. Biodegradable plastics and recycled polymers are gaining popularity, especially among eco-conscious consumers and businesses. These alternatives can provide the same level of performance while reducing your project's carbon footprint. Additionally, understanding the processing characteristics of the materials will aid in optimizing your molding process, ensuring smooth operation and high-quality output. Evaluating performance requirements alongside sustainability goals will guide you in making an informed material choice, setting the foundation for your small run injection molding success.

Step-by-Step Process: How to Develop a Successful Small Run Injection Molding Plan

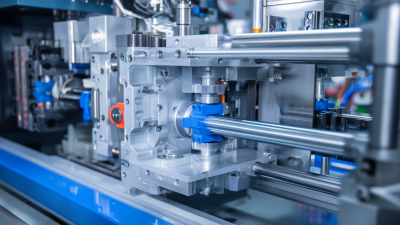

When developing a successful small run injection molding plan, it's essential to understand the intricate steps involved in the process. The first step is to clearly define your project demands, including material specifications, dimensions, and production volumes. In recent industry news, the growing interest in PEEK materials, which are recognized for their excellent mechanical properties and heat resistance, illustrates the importance of selecting the right materials tailored to your specific application. This strategic choice can significantly impact the quality and performance of the final product.

Following the initial planning, the next phase involves selecting a reliable injection molding partner. With domestic companies making strides in PEEK production and breaking through previous market barriers, it’s vital to collaborate with manufacturers adept in working with advanced materials. Ensuring that your partner has expertise in small batch production techniques will not only streamline the development process but also enhance the ability to quickly adapt to any design changes, providing more flexibility and efficiency in your project workflow.

Injection Molding Process Efficiency

Evaluating and Selecting a Reliable Injection Molding Manufacturer

When looking to source small run plastic injection molding services, selecting a reliable manufacturer is critical to ensuring quality and efficiency. The first step in evaluating potential partners is to investigate their experience and expertise in the industry. Manufacturers with a robust portfolio of successful projects are more likely to understand the technical nuances of injection molding. Consider asking for case studies or references from similar projects to gauge their capabilities.

Additionally, communication plays a vital role in building a successful partnership. A manufacturer who is responsive and transparent about processes can alleviate concerns and provide insights that are essential for decision-making. Look for suppliers who are willing to engage in discussions about design, material selection, and production timelines. This collaborative approach not only fosters trust but also helps in troubleshooting potential issues before production begins. Taking the time to conduct thorough due diligence on these aspects will greatly enhance the likelihood of a smooth production process tailored to your specific needs.

Cost Breakdown: What to Expect for Small Run Plastic Injection Molding Projects

When embarking on a small run plastic injection molding project, understanding the cost breakdown is essential. Costs can vary widely depending on several factors including the complexity of the design, materials used, and the production volume. For a typical project, expect to allocate funds for mold creation, machine time, labor, and raw materials. Often, the biggest upfront cost is the mold itself, which can range from a few thousand to tens of thousands of dollars. This investment is crucial as it significantly impacts the overall efficiency and quality of the production process.

**Tip:** To keep costs manageable, consider optimizing your design for moldability. Simplifying the geometry of your part can reduce the complexity of the mold, thereby lowering production costs without sacrificing quality. Additionally, selecting the right material is equally important. Some materials may be cost-effective upfront but could lead to increased expenses during production if they complicate the process or require special handling.

Finally, be mindful of the production run size. While small runs typically provide flexibility, they can also drive up costs per unit. Hence, it's beneficial to evaluate your long-term needs. If you anticipate repeat orders, negotiating for a larger initial batch might save you money in the long run. Planning ahead will ensure that you achieve a balance between quality, efficiency, and budget.

Ultimate Guide to Small Run Plastic Injection Molding for Global Buyers - Cost Breakdown

| Item | Description | Unit Cost ($) | Quantity | Total Cost ($) |

|---|---|---|---|---|

| Mold Design | Initial mold design and engineering | 1,500 | 1 | 1,500 |

| Material Cost | Plastic resin for production | 2 | 100 | 200 |

| Production Cost | Cost per cycle of injection molding | 0.50 | 100 | 50 |

| Finishing Costs | Post-production finishing and quality checks | 3 | 100 | 300 |

| Total | 2,050 |

Related Posts

-

Mastering the Art of Injection Molded Parts Production A Comprehensive Tutorial on Techniques and Best Practices

-

The Definitive Ultimate Guide to Sourcing the Perfect Injection Machine for Your Business Needs

-

10 Reasons Rapid Injection Molding is the Best Choice for Your Production Needs

-

5 Essential Tips for Sourcing Small Run Plastic Injection Molding: A Global Buyer’s Guide

-

Injection Mold Maker Comparison Analyzing Cost Efficiency and Quality in Different Manufacturing Techniques

-

Global Success of Medical Injection Molding from China Driven by Quality Enhancement