The Definitive Ultimate Guide to Sourcing the Perfect Injection Machine for Your Business Needs

In today's competitive manufacturing landscape, selecting the right injection machine is crucial for businesses aiming to optimize production efficiency and product quality. This comprehensive guide is designed to navigate you through the intricate process of sourcing the perfect injection machine tailored to your specific requirements.

Whether you are a seasoned manufacturer or a newcomer in the industry, understanding the key features, technologies, and considerations involved in the purchasing process is essential. From evaluating machine specifications to assessing supplier reliability, this guide covers all aspects necessary to make an informed decision. Join us as we explore the world of injection machines and provide you with the insights needed to elevate your production capabilities and drive your business success.

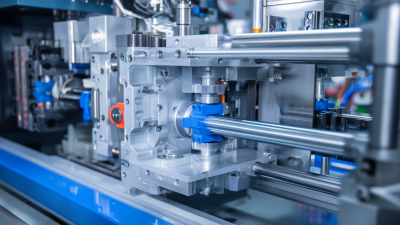

Understanding the Different Types of Injection Machines Available in the Market

When it comes to selecting the right injection machine for your business, understanding the various types available in the market is crucial. The injection molding industry is currently experiencing remarkable growth, with the market projected to expand significantly from USD 365.22 billion in 2024 to USD 580.44 billion by 2033. This growth is driven by increasing demand for plastic products across various sectors, which in turn fuels the need for different types of injection molding machines.

There are several categories of injection machines to consider, including hydraulic, electric, and hybrid models. Hydraulic machines are well-known for their power and ability to handle large volumes, making them ideal for producing larger parts. In contrast, electric machines offer precision and energy efficiency, which can lead to lower operating costs. Additionally, the rise of specific markets, such as micro injection molding, indicates a shift towards smaller, more specialized machines that cater to niche applications. Understanding these differences will not only aid in making an informed investment but also ensure that the chosen machine aligns with your production goals and environmental considerations.

Key Benefits of Choosing the Right Injection Machine for Your Production Needs

Choosing the right injection machine is crucial for optimizing production processes in any manufacturing business. According to a report by MarketsandMarkets, the global injection molding machinery market is expected to reach USD 12.2 billion by 2025, growing at a CAGR of 4.2%. Selecting the perfect injection machine can significantly enhance product quality, reduce cycle times, and lower operating costs. A tailored machine not only meets specific part requirements but also increases production efficiency, directly impacting your bottom line.

Tips: When sourcing an injection machine, consider the materials you will be processing. Different machines are designed to handle various thermoplastics and thermosetting materials, so it's essential to match your machine's capabilities to your production needs. Additionally, evaluate the machine's energy consumption, as energy-efficient models can reduce costs and improve sustainability efforts.

Investing in a reliable injection machine can boost your business's competitive edge. Industry statistics indicate that companies that upgrade to advanced machinery can see productivity increases of up to 30% within the first year. Hence, understanding your production volume and flexibility needs is fundamental when searching for an injection machine that aligns with your operational goals.

How to Assess Your Business Requirements for Injection Molding

When considering the acquisition of an injection molding machine, understanding your business requirements is paramount. Begin by evaluating the types of products you plan to manufacture. Different materials and product designs may necessitate specific machine capabilities. For instance, if you are producing intricate components, a machine with advanced precision features will be essential. Analyzing your product range helps ensure that the machine’s capabilities align with your production goals.

**Tip:** Create a checklist of your product specifications, including dimensions, materials, and production volumes. This will serve as a clear guide during your sourcing process.

Next, assess the scale of your production. Are you looking to produce small batches for prototyping or large runs for retail distribution? The answer will influence the size and type of injection machine you need. Machines vary greatly in capacity and speed; understanding your production rate requirements can help you avoid bottlenecks and inefficiencies.

**Tip:** Consider future growth. Investing in a machine that can accommodate increased production demands can save you from needing another investment down the line. A machine with modular capabilities can adapt to changing needs seamlessly.

The Demand for Injection Molding Machinery by Industry (2023)

Comparing the Cost-effectiveness and Efficiency of Various Injection Machine Types

When it comes to sourcing the perfect injection machine for your business, understanding the cost-effectiveness and efficiency of various machine types is crucial. Recent data from the Plastics Industry Association indicates that electric injection molding machines, while initially more expensive, can lead to significant savings over time, boasting a 20-40% reduction in energy costs compared to hydraulic machines. This is particularly important for businesses aiming to enhance their sustainability efforts while also maintaining profitability.

Moreover, the efficiency of different injection machine types varies not only in terms of energy consumption but also in cycle times and precision. According to a report from MarketsandMarkets, servo-driven hydraulic machines have gained popularity due to their ability to offer the speed and efficiency of electric machines while still providing the flexibility needed for heavy-duty applications. This balance between cost and efficiency can drastically impact a company’s bottom line, as faster cycle times mean increased production rates and lower labor costs per part produced. Therefore, businesses must carefully consider these factors when selecting an injection machine type that best aligns with their operational needs.

Future Trends in Injection Molding Technology and Their Impact on Sourcing Decisions

As the landscape of injection molding technology evolves, businesses must stay attuned to future trends that could significantly affect their sourcing decisions. One of the most notable advancements is the rise of automation and smart manufacturing. Incorporating intelligent controls and data analytics not only improves efficiency but also minimizes waste. This technological shift encourages companies to consider machines that integrate seamlessly with Industry 4.0 frameworks, enhancing connectivity and operational productivity.

Another key trend is the increased focus on sustainability within the injection molding industry. As consumer demand for eco-friendly products rises, manufacturers are actively seeking machines that can utilize recycled materials and reduce energy consumption. Investing in biodegradable polymers and low-energy injection systems can set a business apart in a competitive market. Therefore, sourcing decisions should prioritize machines that align with sustainable practices, ultimately catering to the changing preferences of consumers and regulatory requirements. Adapting to these trends ensures that businesses remain competitive and responsible in their production processes.

The Definitive Ultimate Guide to Sourcing the Perfect Injection Machine for Your Business Needs - Future Trends in Injection Molding Technology and Their Impact on Sourcing Decisions

| Dimension | Description | Impact on Sourcing | Future Trends |

|---|---|---|---|

| Machine Type | Hydraulic, Electric, and Hybrid | Selection depends on production volume and precision needs. | Increase in electric machines due to energy efficiency. |

| Clamping Force | Measured in tons, dictates mold size and type. | Critical for ensuring mold integrity during operation. | Development of machines with adaptive clamping technologies. |

| Injection Speed | Speed of injecting material into the mold. | Affects cycle times and product quality. | Improvements in servo-driven systems for faster cycles. |

| Control Systems | Types include PLC, PC-based or closed-loop systems. | Enhances precision and monitoring during operation. | Increased integration with IoT for real-time data analysis. |

| Material Compatibility | Capability to process various polymers and composites. | Influences production flexibility and part properties. | Emergence of machines equipped for bio-based materials. |

| Energy Efficiency | Energy consumption per cycle of production. | Lower operational costs and environmental impact. | Adoption of energy-efficient technologies and designs. |

Related Posts

-

Injection Mold Maker Comparison Analyzing Cost Efficiency and Quality in Different Manufacturing Techniques

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape

-

Global Success of Medical Injection Molding from China Driven by Quality Enhancement

-

10 Reasons Rapid Injection Molding is the Best Choice for Your Production Needs

-

Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques