Unlocking the Future of Product Development with Rapid Injection Molding Techniques

In today's fast-paced industrial landscape, the demand for efficient and innovative product development methods continues to grow. Rapid injection molding has emerged as a revolutionary solution, enabling companies to accelerate prototyping and production while significantly reducing costs. This technique allows for the swift transition from concept to tangible product, making it a preferred choice for businesses looking to stay ahead of the competition. By harnessing the capabilities of rapid injection molding, manufacturers can quickly iterate designs, test new ideas, and bring high-quality products to market with unprecedented speed. This article will guide you through the transformative potential of rapid injection molding, exploring its processes, advantages, and best practices to unlock a new realm of possibilities in product development. Join us as we delve into the future of manufacturing that is characterized by rapid responsiveness and enhanced creativity, paving the way for innovative products that meet the ever-evolving needs of consumers.

Understanding Rapid Injection Molding: A Comprehensive Guide

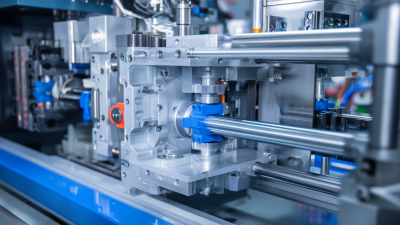

Rapid injection molding is revolutionizing product development by significantly shortening the time required to bring concepts to market. This innovative technique allows for the rapid production of high-quality plastic parts, making it especially beneficial for industries that demand quick turnaround times, such as consumer electronics and automotive. By utilizing advanced technologies and streamlined processes, companies can create prototypes and finalize designs faster than ever, enabling a more agile response to market demands.

Understanding the intricacies of rapid injection molding is essential for companies looking to leverage its benefits. This method typically involves the use of aluminum molds, which are less expensive and can be produced quickly compared to traditional steel molds. Furthermore, rapid injection molding allows for simultaneous production and testing, facilitating adjustments and iterations that can lead to better-end products. By mastering these techniques, businesses can enhance their development cycles, reduce costs, and maintain competitive advantages in an ever-evolving marketplace.

Unlocking the Future of Product Development with Rapid Injection Molding Techniques

Key Benefits of Rapid Injection Molding in Product Development

Rapid injection molding is transforming the landscape of product development by offering significant advantages that streamline the manufacturing process. One of the key benefits is the reduction in lead times. Traditional injection molding methods can be time-consuming, often requiring weeks to develop molds and prototype products. In contrast, rapid injection molding can drastically cut this timeline to just a few days, allowing companies to bring their products to market more quickly.

This agility is particularly valuable in fast-paced industries where consumer preferences evolve rapidly.

Additionally, rapid injection molding enhances cost efficiency, especially for low to medium production runs. By utilizing advanced technologies such as 3D printing for mold creation, manufacturers can minimize material waste and reduce upfront costs associated with tooling. This makes it more feasible for businesses to test multiple design iterations without breaking the bank.

The ability to produce high-quality prototypes and functional parts quickly also enables better collaboration and feedback during the development phase, resulting in refined products that better meet market demands. Overall, rapid injection molding is a game-changer that empowers firms to innovate faster and more economically.

Step-by-Step Process of Implementing Rapid Injection Molding Techniques

Rapid injection molding techniques are revolutionizing product development by integrating advanced technologies such as three-dimensional printing and hybrid deep learning approaches. The process of implementing these techniques involves several critical steps, starting with the design and manufacturing of molds. Recent advancements in this area highlight the significance of utilizing 3D-printed molds, which allow for faster prototyping and iterations. Studies indicate that employing rapid tooling can reduce lead times by up to 50%, significantly benefiting industries that rely on swift market responses.

Moreover, the integration of intelligent manufacturing concepts, such as adaptive PID control enhanced by deep reinforcement learning, has emerged as a game-changer for hydraulic servo systems in injection molding machines. This novel approach not only improves process efficiency but also optimizes the quality of manufactured parts. Research has shown that using hybrid optimization techniques, combining artificial neural networks with genetic algorithms, can effectively address multiple objectives in the injection molding process, including reducing defects like sink marks and shrinkage, leading to enhanced product reliability. These innovations underscore the potential of rapid injection molding as a vital tool for meeting the increasing demands of speed and precision in product development.

Common Challenges and Solutions in Rapid Injection Molding

Rapid injection molding has revolutionized the product development landscape, but it comes with its own set of challenges. One common issue is the high upfront cost associated with tooling. According to a report by Mordor Intelligence, the global injection molding market was valued at approximately $300 billion in 2020 and is projected to grow significantly. However, achieving cost efficiency requires optimizing the design and material selection process to minimize waste and reduce expenses in the long run.

Another challenge is maintaining quality in rapid production. With shorter lead times, manufacturers may face difficulties in ensuring consistent quality across batches. A survey by the Plastics Industry Association indicated that 70% of manufacturers cite quality control as a critical challenge in rapid molding practices. Implementing stringent quality assurance protocols and investing in advanced inspection technologies can effectively address these concerns.

Tips: To enhance your rapid injection molding process, invest in simulation software that helps predict mold behavior and identify potential issues before production. Also, consider using high-performance materials that can withstand rapid cycles, thus reducing the likelihood of defects and increasing overall efficiency. By proactively addressing these challenges, companies can harness the full potential of rapid injection molding, paving the way for innovative product development.

Future Trends: Innovations Enhancing Rapid Injection Molding Practices

The rapid injection molding sector is witnessing significant innovations that are poised to reshape product development. According to a recent report by MarketsandMarkets, the rapid injection molding market is expected to grow from USD 1.1 billion in 2022 to USD 2.3 billion by 2026, reflecting a compound annual growth rate (CAGR) of 15.6%. This growth can largely be attributed to the increasing demand for faster product turnaround times and the need for cost-effective prototyping solutions, aligning with the agile methodologies that businesses are adopting to stay competitive.

Innovations such as the integration of advanced materials and 3D printing technologies are enhancing the efficiency of rapid injection molding practices. For instance, the adoption of biocompatible materials is gaining traction, catering to the ever-expanding healthcare and medical devices sector. Additionally, the use of simulation software allows for optimized mold designs and process parameters, significantly reducing production lead times.

As outlined in a report by Deloitte, the fusion of traditional manufacturing with digital technologies is set to facilitate better quality control and reduce waste, making rapid injection molding an even more attractive option for manufacturers aiming to innovate swiftly and sustainably.

Related Posts

-

Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques

-

Global Success of Medical Injection Molding from China Driven by Quality Enhancement

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

10 Reasons Rapid Injection Molding is the Best Choice for Your Production Needs

-

Mastering the Art of Injection Molded Parts Production A Comprehensive Tutorial on Techniques and Best Practices

-

Ultimate Guide to Mastering Plastic Molding Techniques for Your Business